Our booms can be divided by their operating principle into direct feed, chain feed and dual mast booms.

Direct feed booms are designed for all types of geotechnical and geological work and are also used in core sampling in rock. Chain feed booms double the speed of operation, and they are particularly suitable for environments where the boom’s operating height is limited, such as railways and tunnels. Our latest innovation is the dual mast boom. It combines the best features of direct feed and chain feed.

Geomachine booms have a double drill table that can be equipped with drilling accessories and investigation equipment to suit customers’ needs. The booms are modular and therefore easy to install also on non-Geomachine carriers, e.g. tractors and excavators.

Geomachine’s light boom is small in size but still suitable for all main investigation methods except for casing drilling and core sampling in rock. The boom can also be used to install small groundwater pipes in shallow groundwater wells.

The light boom comes in two lengths and is the standard boom in the GM50GT drill rig. The boom can also be mounted on other lightweight carriers besides Geomachine rigs.

Chain feed booms offer double the movement speed compared to direct feed booms, making them excellent options for medium-duty geotechnical investigations where drilling speed is the key driver. Chain feed boom is particularly suitable for environments with restrictions on the boom’s operating height, such as railway works and tunnels.

The boom is found as standard in the GM75GT drill rigs, and it is also a popular option for the GM85GT and the GM8GT rigs. Like all Geomachine booms, the chain feed boom can be installed on non-Geomachine carriers with sufficient hydraulic output.

The medium-duty boom is suitable for all medium-duty survey sites and the most common investigation methods. The boom has a side-shifting dual drill table, and the tables can be configured according to the desired investigation methods.

This boom can be found as standard on the GM85 drill rig. Like all Geomachine booms, medium-duty booms can also be installed on non-Geomachine carriers with sufficient hydraulic output.

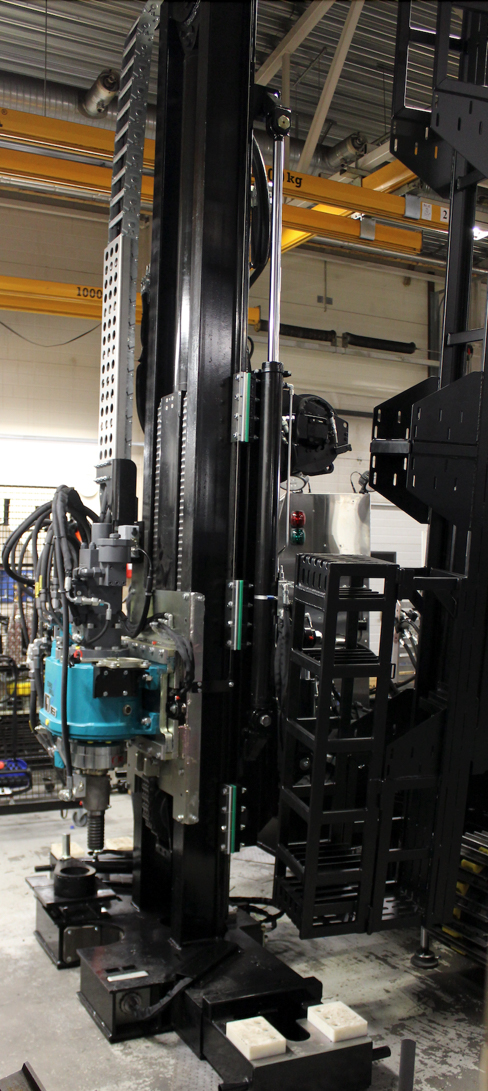

The heavy-duty boom is designed for the most challenging sites. It is at its best in percussion drilling and static-dynamic penetration tests. A direct cylinder feed moves the boom with excellent reliability. Offering more compression and lifting force than the other Geomachine booms, this robust boom is suitable for the deepest sites in varying soil conditions. It is equipped with Geomachine’s most powerful rotation heads and a powerful hammer. Hydraulic side shifting makes switching between drill tables fast and easy.

The heavy-duty boom comes as standard within the GM100 and GM200 rigs, and it can also be installed on non-Geomachine carriers with sufficient hydraulic output.

The heavy chain cylinder boom moves fast and is suitable for low spaces. The boom is significantly more powerful than a medium-duty boom, allowing for higher feed and lifting forces. The drill tables can be fitted with more powerful rotary heads and a hammer, making it possible to carry out investigations in the most challenging sites. Hydraulic side shifting makes switching between drill tables and methods easy. Like the smaller chain feed boom, this boom also excels in railway work and other conditions where the working height is limited.

Besides heavy-duty Geomachine drill rigs, the heavy chain cylinder boom can be installed on non-Geomachine carriers with sufficient hydraulic output.

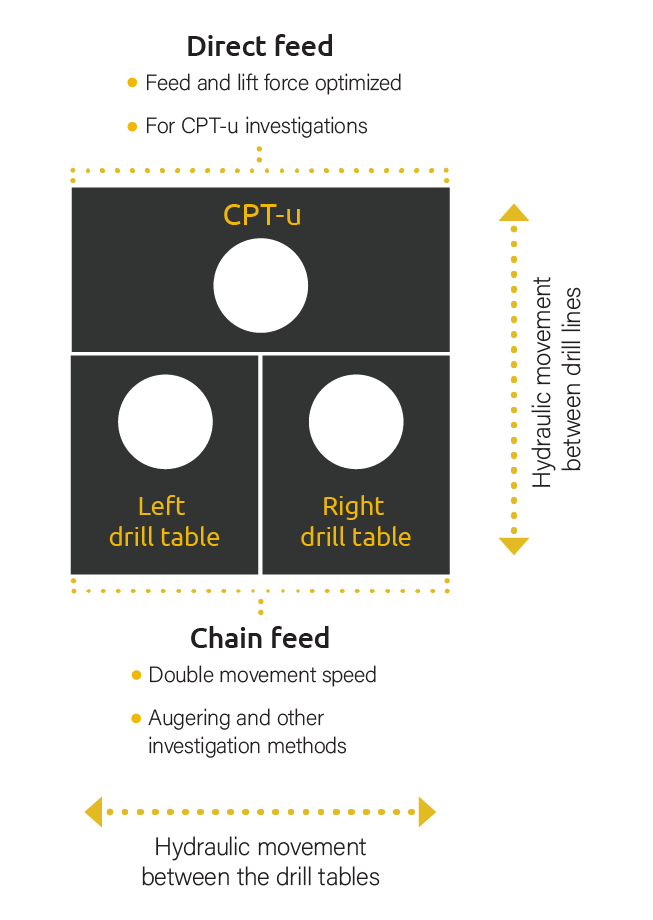

The dual mast boom is one of the latest GM innovations. Its patented technology combines the best features of direct and chain feed booms into one package that helps to optimise the efficiency in CPT-u investigations in particular. The chain feed line speeds up the operations, whereas the direct feed line allows the cylinder’s maximum compression and lifting force.

Although optimised for the CPT-u method, the dual mast boom is equipped with a dual drill table that allows it to be used for all other geotechnical investigations as well. Switching the drill line from the direct feed to the chain feed takes place by a hydraulic cylinder. The dual drill table also allows a fast and effortless automated switching between investigation methods.

The dual mast boom can be installed on Geomachine drill rigs from the GM85 upwards. It can also be installed on non-Geomachine carriers with sufficient hydraulic output.

Geomachine’s diamond coring equipment is designed for ore prospecting and can be used for sampling from both soil and bedrock. Still, for rock sampling, geological drill booms must be equipped with a higher-speed diamond coring chuck, a bottom brake designed for diamond coring and a roller lift.

The chuck’s maximum outer diameter of 77.5 mm enables drilling with various equipment. Wireline equipment can be used with an extension boom mounted on the boom. The correct rotation head torque and speed are selected based on the equipment specific rotation speed requirements and the target drilling depths.

Geological booms also have a dual drill table, allowing the other drill line to be used, e.g. for auger or percussion drilling. Switching between the methods is fast.

The boom can be mounted on Geomachine GM100 or GM200 drill rigs. Diamond coring rig is also always equipped with a convenient work platform and a safety cage, which enables drilling at different angles according to the customer’s sampling needs. Like the geotechnical booms, the diamond coring equipment can also be installed on customer-specific carriers as long as they have sufficient hydraulic output.

The booms are controlled electronically, and all survey data can be stored in the GMTracker DTH data-logger software. The results and coordinates can be shared via the GM cloud service.