Geothermal Energy Capture Increased Over 60 Times

21.08.2023

QHeat

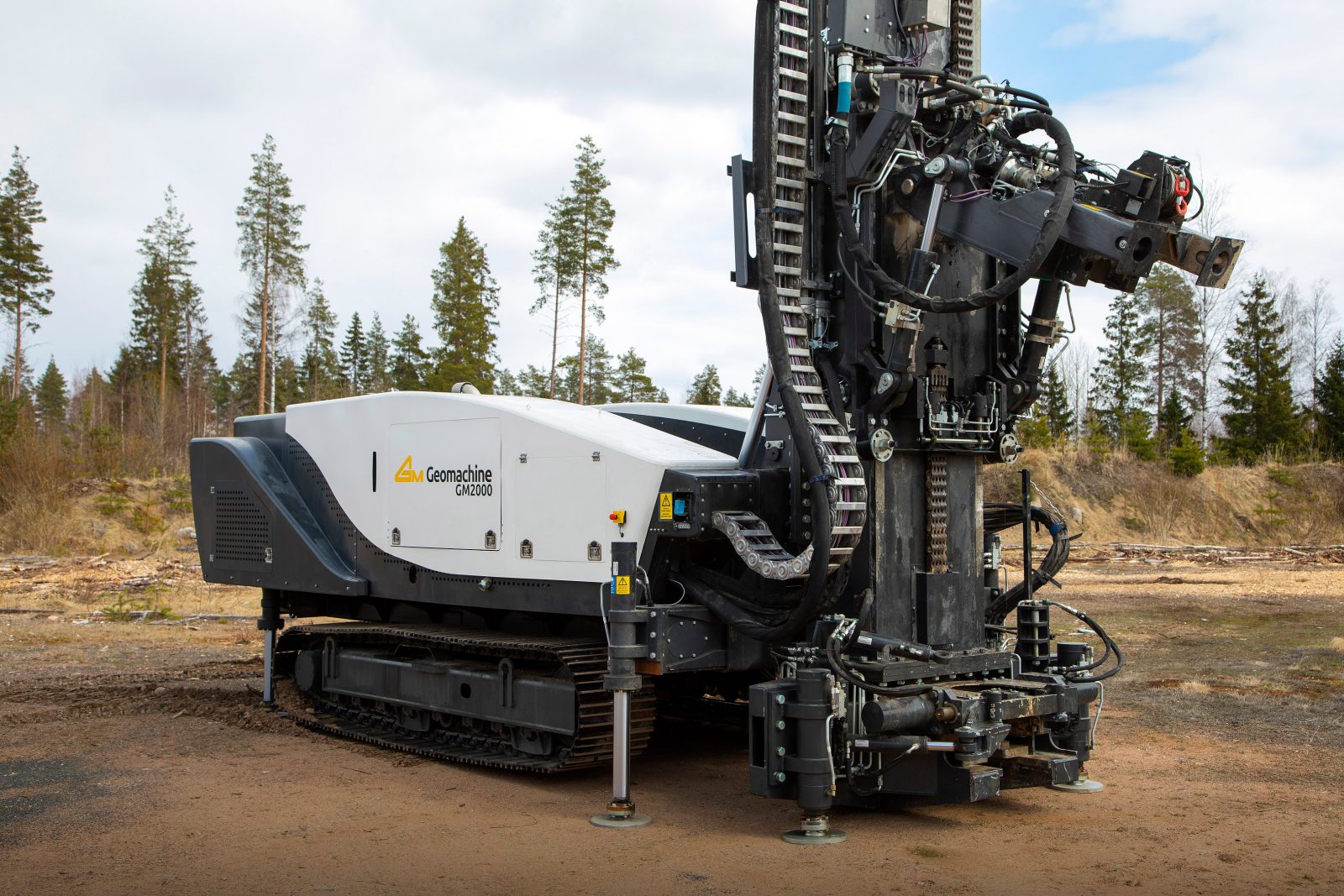

Thanks to the new geothermal solution introduced in March 2023, geothermal heat is now being captured from depths exceeding 2000 metres. The developer behind this solution is the technology company QHeat. Well drilling is carried out using Geomachine’s GM2000 technology.

“Deep drilling has been a practice in the oil and gas sector for a long time,” begins Erika Salmenvaara, CEO of QHeat. “However, in traditional geothermal drilling, the depth has only been around 300 metres. With our newly developed geothermal well solution, we are now able to utilise geothermal energy from up to 2000 metres deep, and possibly even deeper in the future. This represents a significant leap in the utilisation of geoenergy.”

QHeat’s new geothermal solution is patented globally. “We will also take our innovation abroad. Energy consumption is continuously increasing, and there is a growing demand for renewable energy sources. Geothermal energy holds immense market potential in Europe, North America, and Asia.”

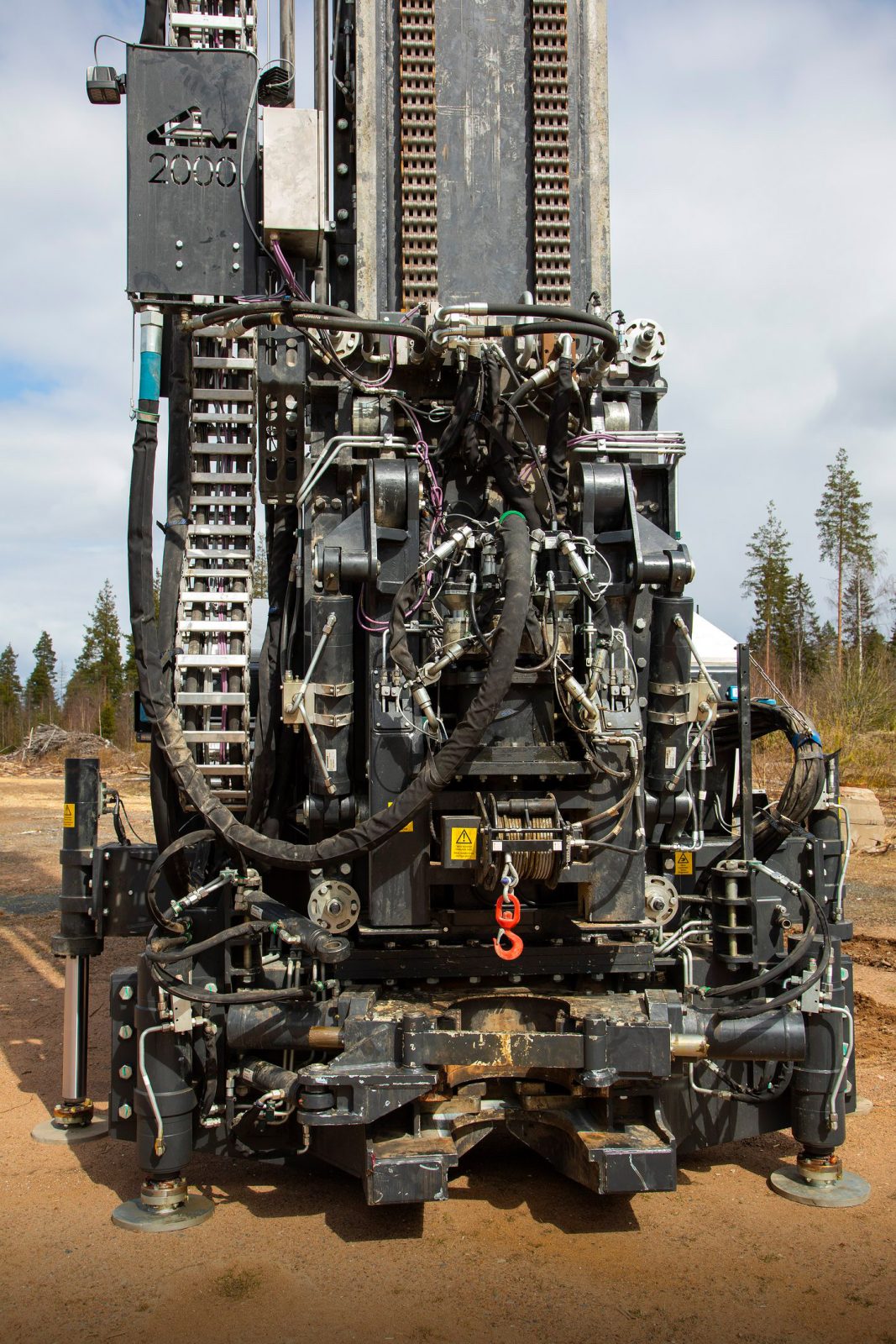

GM2000 takes centre stage in drilling

The drilling of wells is performed using Geomachine developed GM2000 well drilling technology. In addition to the well drilling rig, the complete solution includes a compressed air system and an intelligent control and recording system for optimising the drilling process. This solution is the first of its kind in the world. “When we started looking for a practical implementer for our innovation a few years ago, we realised that there was no expertise in deep geothermal well drilling in Finland. Geomachine has decades of experience in ground investigation and down-the-hole hammer drilling, so we engaged in discussions about refining our concept with them. It became clear that they had the expertise needed to develop the drilling rig.”

In designing the GM2000 well drilling rig, special attention has been given to overall cost-effectiveness, automatic data recording, real-time analysis of the drilling process, and work safety. “The adoption of the GM2000 solution has brought various benefits. Drillers’ job satisfaction has improved because they now have a modern tool at their disposal. Work is safer, and drillers are no longer exposed to emissions as the rig can be controlled remotely. Due to the rig’s data-driven control, the driller knows what is happening in the hole at all times. Overall, work has become safer and of higher quality.”

In action at a waste incineration plant

The world’s first GM2000 well drilling rig was put into operation in March 2023 at the request of Lounavoima, a waste incineration plant in Salo, Finland. “Our customer specifically required the use of this solution for their site. In addition to greater drilling depth, safety during work was important to our customer.”

At the Lounavoima waste incineration plant, deep geothermal wells are primarily used for heat storage. “The plant generates a steady stream of energy for the district heating network. However, the heat demand on the network constantly varies. During periods of low consumption, the plant has generated excess heat. This excess heat can now be stored in deep geothermal wells and later released when demand increases. This solution was not previously used at waste incineration plants, so we are implementing it here as the first in the world.”

The Lounavoima project began in 2021 with a different drilling rig, and now it continues with Geomachine’s GM2000 solution. “The plan is to drill two more geothermal wells this year, totaling three wells at the site. Overall, the goal is to create a heat storage consisting of six wells.”

Clear numbers tell the story

Before the introduction of the GM2000 well drilling rig, the record drilling depth for geothermal wells was 1600 metres. The ability to now drill to 2000 metres, and potentially even deeper in the future, takes the utilisation of geothermal energy to a whole new level. “The drilling depth has been increased by a third, which means that now we can capture 60% more energy than before. From a 1500-metre deep well, we obtained 950 megawatt-hours annually, and from a 2000-metre deep well, we can now obtain 1530 megawatt-hours. This is a remarkable improvement!”

The numbers are even more impressive when comparing the energy output of a 2000-metre deep well to a traditional 300-metre deep geothermal well. “Compared to a traditional well, we can now capture over 60 times more energy from a single well.”

In the future, the GM2000 solution will benefit especially large real estate properties where the solution can be used as a regional energy source. The energy from a single well is sufficient to heat even 300 energy class A apartments size of 70 m².

“In the future, we will market our solution especially to large property owners, professional real estate investors, construction companies, district heating producers, and district heating companies. The target must be large enough to optimally benefit from our solution.”

Authentic collaboration

According to Erika Salmenvaara, the collaboration with Geomachine is an excellent example of how combining forces can lead to an excellent outcome. “Our mission is to assist our customers on their carbon neutrality journey, particularly in heating. Our product is clean heating energy. Geomachine, on the other hand, offers the solution for practically implementing our mission. Even though we operate in different industries, we have found true synergy in achieving a common good.”

Both QHeat and Geomachine benefit from this collaboration in growing their respective businesses. “For us, collaboration enables us to sell our innovation as a tangible product to those who need it. Geomachine, on the other hand, adds a new solution to their product portfolio, expanding their offerings from ground investigation to geothermal energy drilling.”

Read more about GM2000 solution here.