The ultimate toolkit for ground investigation

15.05.2025

Geomachine

Geomachine’s range of drilling rigs covers all the needs of ground investigation. The fleet currently includes seven versatile rigs designed for various levels of challenging investigations. Each rig is packed with superior technical features, usability, and intelligence.

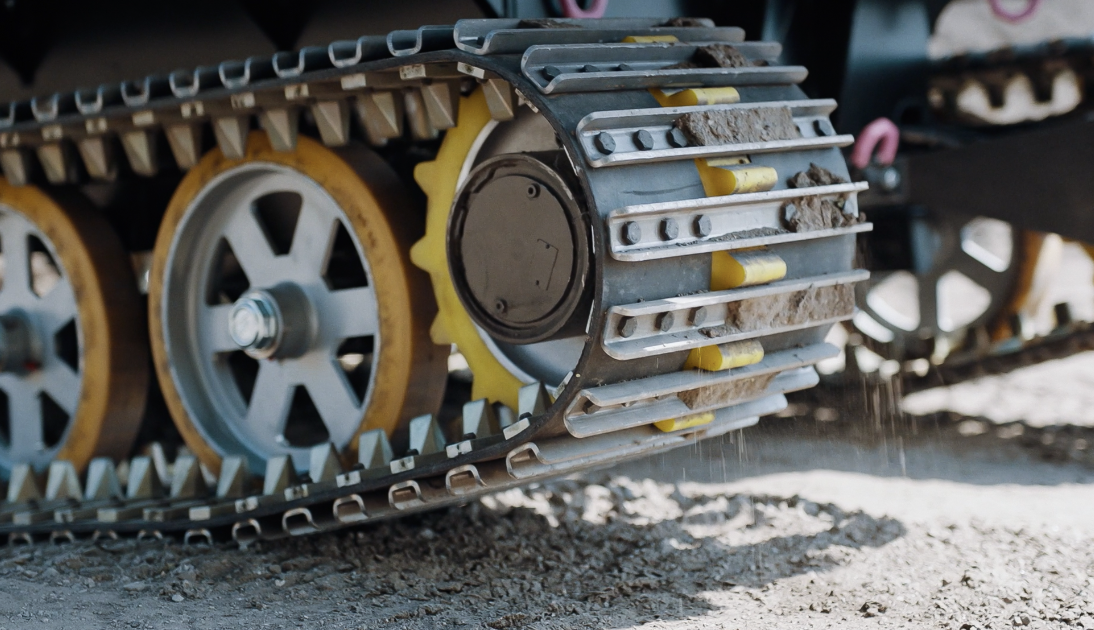

The smallest rig in Geomachine’s product family is the two-ton GM50, which can be transported on a car trailer. The flagship model is the eight-wheeled GM8 mammoth, capable of traversing even the most difficult terrains with low ground pressure. The core of the machine lineup consists of the GM75, GM85, and GM100, multi-purpose machines highly valued by ground investigation professionals.

All Geomachine drilling rigs are designed and manufactured in Finland. Each rig operates flawlessly in varying soil conditions, challenging terrains, as well as in snowy and harsh weather. The largest geotechnical drilling rigs are also excellently suited for geological investigations when equipped with diamond drilling equipment.

Modularity brings customization

All Geomachine drilling rigs are modular. This ensures that customers always have access to the most suitable tool without expensive customization costs or long delivery times.

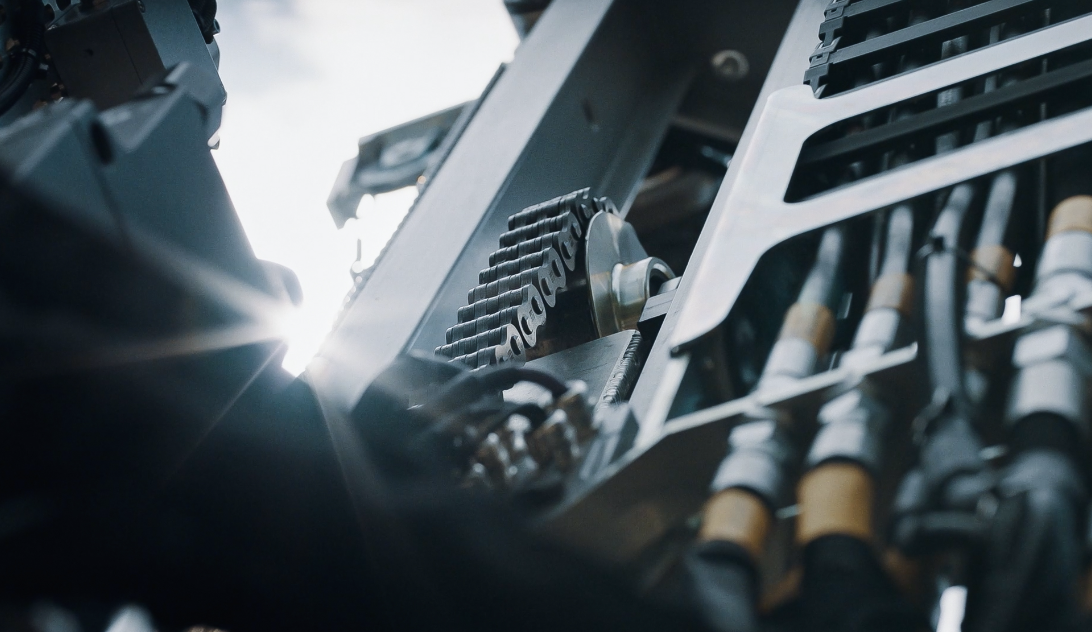

In practice, modularity means that the machine base can be equipped with the most suitable boom. The boom range includes several innovative and durable options and can be categorized based on their operating principles into direct feed, chain feed, and dual mast booms. All boom types can also be installed on platforms other than Geomachine’s own, provided they have sufficient hydraulic output. In addition to drilling rigs, they are also suitable for tractors, excavators, and barges.

An essential part of the machines’ modularity is the dual drill table in Geomachine’s booms, which can be equipped with drilling and investigation equipment tailored to the user’s needs.

The power source of the machine can also be selected according to needs. For those prioritizing zero emissions and quiet operation, an electric motor package is the right choice. The diesel engines used in Geomachine’s drilling rigs meet the strictest Stage 5 emission standards and can be operated with renewable diesel.

Most valued features

Geomachine’s products are always developed to serve genuine customer needs. Year after year, customers highly value ergonomics, usability, and safety in operations. Therefore, these features are always standard in all Geomachine ground investigation rigs.

A crucial factor affecting work ergonomics is the control panel positioned at the right height. Geomachine’s machine control panels have multi-directional adjustability, allowing the panel to be set at an optimal height even on uneven terrain.

Usability is further enhanced by the fact that all machine models today have very similar operational functions. This means that once the operating principle of a tool is learned, it doesn’t need to be relearned when switching machine models.

Safety features in Geomachine’s machines are also at a high level. Work safety is improved by features such as remote control enabled by the electronic IQAN control system and a separate rod-changing area.

Intelligent working

The ground investigation business follows the same principles as business in general. The ultimate goal is always to operate as qualitatively, productively, and profitably as possible. The investigation process itself is quite standardized today. The most productive detail for the entire process is how qualitatively the investigation data can be captured and how diversely it can be utilized.

Geomachine stands out from its competitors with the intelligence of its products. When all of Geomachine’s digital services are activated, the operator is equipped to efficiently and data-drivenly perform the most critical key tasks of all investigation projects.

Project profitability improves immediately as supply chains become transparent, equipment downtime decreases, equipment management improves, and unnecessary manual work becomes a thing of the past for all members in the project’s value chain. In the long term, project productivity further increases because, thanks to machine learning, investigation work as well as machine maintenance and servicing become more predictive. As the knowledge base on operations and equipment performance diversifies, it helps make the overall operation increasingly profitable.

Uncompromising quality for frontline professionals

Geomachine’s products and services are the right choice for industry operators who are not satisfied with merely completing the work but aim to conduct investigations more intelligently and with higher quality continuously. This means that only top-class tools are acceptable, and they must also be ready to meet future challenges. In the future, those who understand the importance of seamlessness in the project members’ value chain will also succeed.

Geomachine aims to help all its customers excel in their work in the best possible way. This is achieved by taking the ground investigation industry to a new, smarter, and more productive era.

Interested? Contact Geomachine!