Ground investigation in the smartest and most modern way

23.04.2025

Geomachine

Geomachine aims to make ground investigation as efficient, profitable, and high-quality as possible. That’s why it develops cutting-edge digital innovations that will lead the industry into a new and smarter era.

Continuous development is deeply embedded in Geomachine’s DNA. In recent years, the company has focused particularly on digital innovations in its product development to enable companies in the ground investigation industry to conduct their business more intelligently and profitably.

“In the ground investigation industry, traditional methods have often been used, resulting in many manual workflows and fragmentation in the value chain,” says Pasi Majakangas, who designs digital services for Geomachine. “Four years ago, we initiated the development process for digital products with the aim of tackling these challenges.”

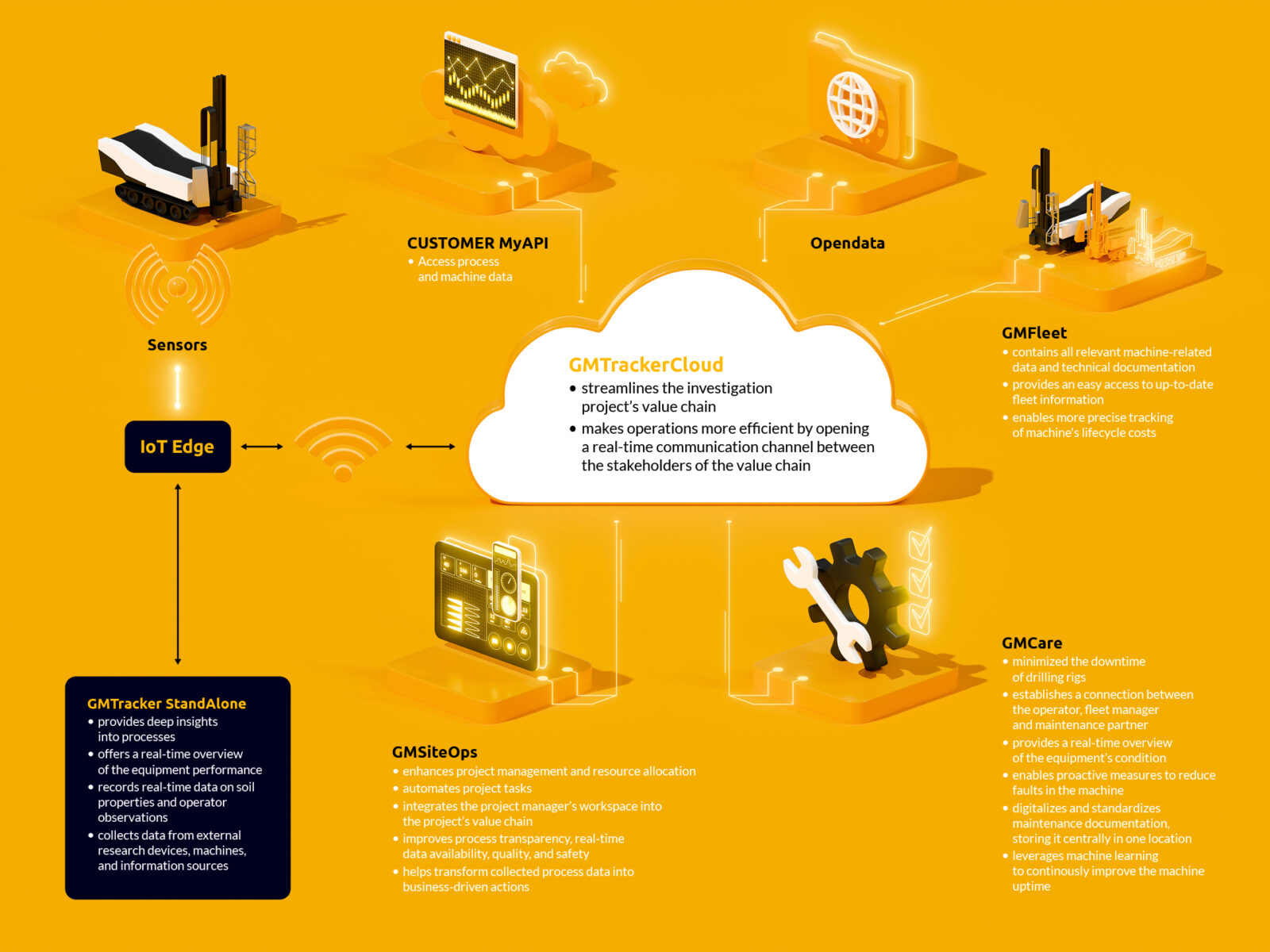

Geomachine’s digital product family currently includes four innovative tools. “The heart of our product family is the GMTracker data-logger. It is an extremely smart tool that provides full visibility into the investigation processes and gives an overview of the performance of the equipment used. In its StandAlone version, GMTracker works locally as an operator tool, and in its Cloud version, it creates a real-time, two-way connection between all project stakeholders. The Cloud version can also be extended with modules such as GMCare, which enhances machine maintenance and servicing, GMSiteOps for optimizing project management and planning, and GMFleet, the equipment registry.”

Step by step forward

As with all of Geomachine’s product development projects, the planning and development of the digital product family involved strong customer collaboration. “In the development of the GMTracker data-logger, we received invaluable support and insights from our long-time customer, Aluetaito Oy. They were involved in the project from the very beginning, and through iterative work, we developed the data-logger to the point where it could be launched to the market.”

The first version of the GMTracker data-logger was made for research methods used in Finland, and later versions were developed for Sweden and Norway. “From a product development perspective, the initial challenge was that there was considerable variation in the needs and practices of companies in the ground investigation industry. A single software solution for everyone was not an option at that point, so the product had to be configured individually for each customer’s specific needs. We focused heavily on customization in our product development. Today, customizing GMTrackerCloud to meet the unique needs of customers can be done with just a few clicks.”

Once the first version of GMTracker and its project management features were up and running, the product development moved forward. “In the next phase, we began considering solutions to enhance machine maintenance and servicing and improve equipment management transparency. These challenges were addressed with the development of the GMCare and GMFleet tools.”

Toolbox expands as needed

According to Pasi Majakangas, no other digital product family like Geomachine’s is currently available on the market. “Until now, individual tools could be purchased from various providers. However, this has resulted in customers having to manage a system architecture that could become messy and difficult to handle. Each program had to be learned separately, and integrating them could require a lot of effort. Managing the whole is now much smarter and easier when all the essential tools can be obtained from one provider.”

One of the strengths of Geomachine’s digital product family is its scalability. “Our products adapt to the needs of the user. You don’t have to purchase the entire extensive toolbox at once; it can be expanded as needed.”

Once all the innovative features of GMTrackerCloud are activated, it provides solutions for the efficient and data-driven execution of the key tasks in ground investigation projects. The transparency of supply chains immediately increases project efficiency, reduces equipment downtime, improves fleet management, and reduces the amount of manual, unnecessary work. In the long term, projects become more productive continuously, as machine learning makes maintenance and servicing operations more predictive. Data on operations and equipment performance constantly increases, helping to make the overall operation more profitable over time.

Continuously smarter and more versatile

Pasi Majakangas says that the development of the digital product family is still ongoing. “In the future, our product family will include even more analytics and 3D visualization features. With these, for example, risk assessments and quality assurance on work sites will be done even more efficiently. The drill rig will learn to identify ground characteristics and automatically suggest them to the driller. Additionally, it will take care of its own maintenance and identify its own issues. This way, maintenance can be performed as soon as the machine starts to show signs of failure, even before an actual breakdown occurs.”

Geomachine’s digital tools are currently in use by leading companies in the ground investigation industry in Finland, Sweden, Norway, and Iceland. “Every ground investigation company that understands that project productivity requires transparency across the value chain can benefit from our innovations. We want to enable our customers to focus on the right things. Do more with less – that’s what we want to offer our customers in a nutshell.”

Interested? Contact Geomachine!