Customer-focused pioneer in ground investigation rigs

21.05.2025

Geomachine

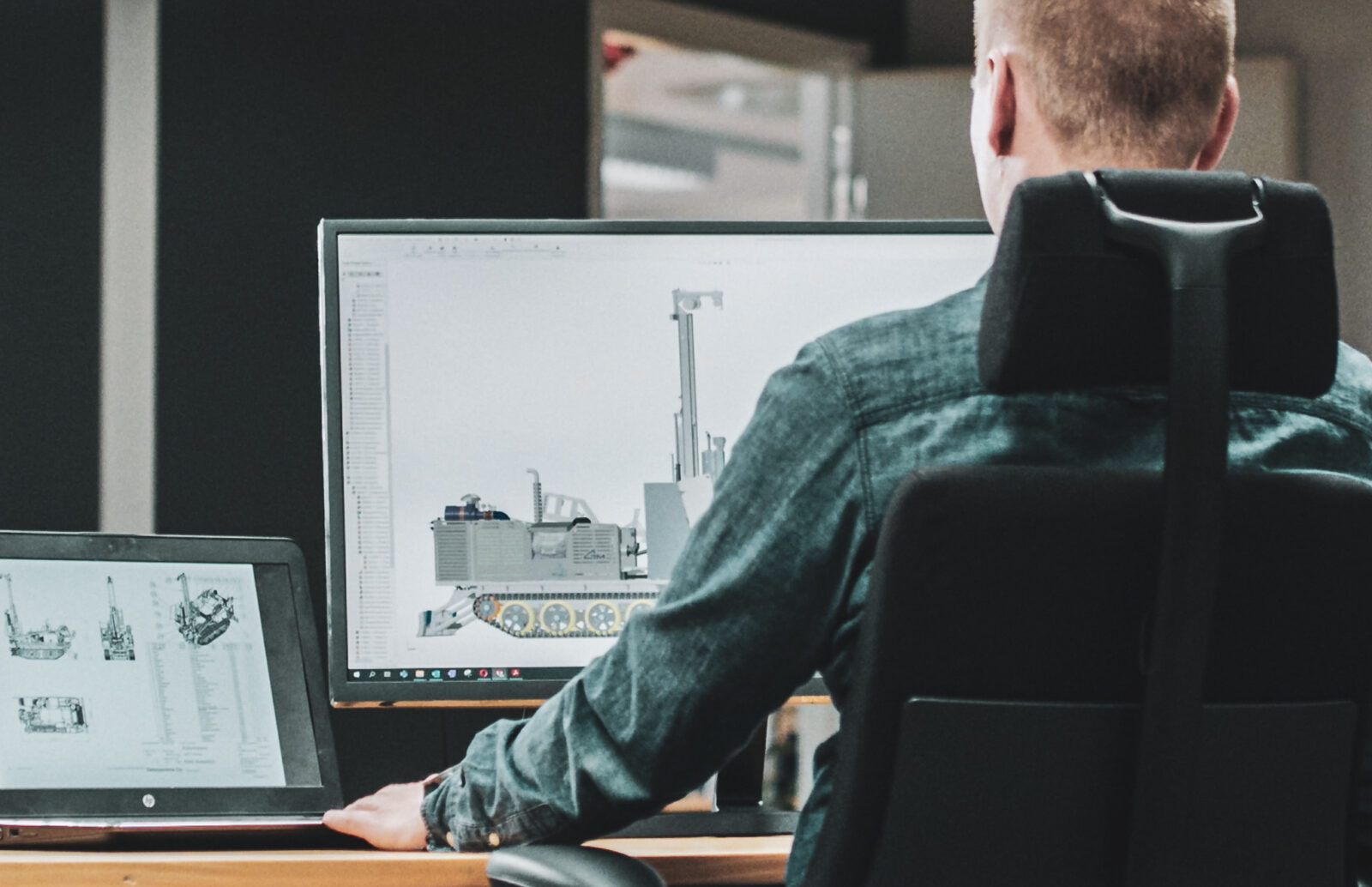

Geomachine has been designing and building ground investigation rigs for the world’s most challenging conditions for over four decades. Today, its product family includes seven different rig models to meet all ground investigation needs.

Geomachine began developing ground investigation rigs in 1984. Until then, investigations in Finnish conditions were conducted manually, and Geomachine sought to explore whether the process could be automated using machinery.

Today, the machine lineup comprises seven rig models capable of performing all investigation methods required for challenging Scandinavian conditions. To meet future demands for zero emissions, Geomachine has also developed the fully electric heavy-duty GMe100 investigation rig, which is suitable for all the same methods as its diesel-powered twin.

Significant advancements have occurred in rig development over recent decades. In the future, development will continue robustly, but its focus areas will evolve.

Cornerstones of rig development

Developing ground investigation rigs is an iterative process. There’s no need to reinvent the wheel each time; instead, new products are often built upon existing foundations. Proven and functional elements are retained, while areas identified through customer feedback are further developed.

According to Geomachine’s Sales Manager, Alexander Packalén, customer feedback is often very concrete. “For example, our GM85 rig model was developed because its predecessor, the GM75, couldn’t accommodate a compressor large enough to meet the customer’s power requirements. Our product family’s giant, the eight-wheeled GM8, came into being because a customer needed to work in rocky and challenging terrains inaccessible to tracked machines. Thanks to its off-road capabilities, the GM8 is in a class of its own and is now used on wind power construction sites, which are often located in remote areas.”

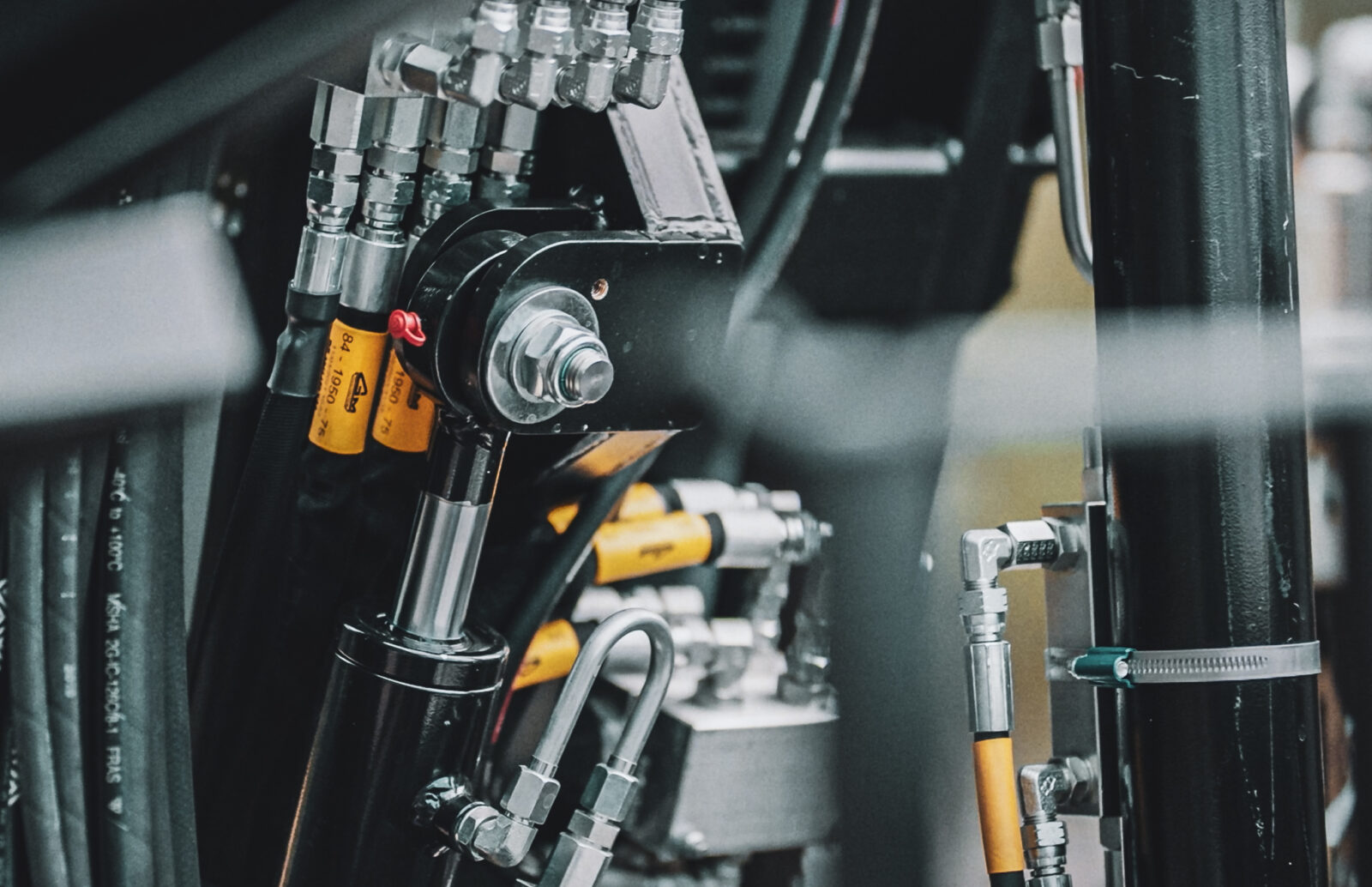

In addition to customer feedback, new product development is guided by legislation, environmental requirements, and the ongoing need for safer and more efficient operations. “In the ground investigation industry, as in other sectors, the pressure for environmental friendliness is continually increasing. Moreover, safety remains a crucial theme today, just as it was decades ago. As investigations become increasingly demanding and diverse, the need for larger machines and additional equipment, such as more powerful compressors, grows.”

When discussing ground investigation, one aspect stands above all. “Data must be collected from the ground with high quality. If this isn’t achieved, nothing else matters. That’s why our most significant focus in product development is currently on enhancing machine intelligence. The heart of our digital product family, the GMTracker data-logger, increases the automation level, efficiency, and data quality of investigation work. In addition to the data-logger, we offer innovative tools for planning and managing investigation projects, maintaining and servicing machines, and managing equipment registers. By adopting these tools, it’s possible to create a seamless value chain for the entire ground investigation process, significantly boosting productivity.”

Smarter, more efficient, and environmentally friendly in the future

Geomachine’s Head of Engineering, Juha Sandholm, notes that there hasn’t been much development in the actual investigation methods in recent years, meaning that the rigs’ basic functions will remain relatively similar. “Where there’s still significant room for improvement is in increasing the intelligence of operations and, consequently, their productivity. We started developing our digital products about four years ago, and this development will continue strongly. Thanks to machine learning, our rigs will become even more analytical and predictive. Unnecessary manual workflows will be eliminated, and machine downtime will be minimized. Information will flow in real-time throughout the value chain, improving project turnaround times and profitability.”

The importance of digitalization will also be emphasized in the future because a new generation of drillers is entering the ground investigation industry. “Fresh, younger professionals are continually joining the field. They naturally live in the digital age, and therefore, a high level of intelligence in tools is an expected standard for them, not just a nice addition. We aim to be the most attractive partner in the market for future ground investigation professionals.”

Electrification is another main theme in future product development. “Our rig models have been available as hybrids since 2021. Recently, we also launched the fully electric GMe100 rig, which is expected to meet the increasingly stringent zero-emission requirements in ground investigation. However, customers’ equipment purchases are often strongly influenced by cost, which currently somewhat slows the transition to electrification. We anticipate that the world will evolve in a direction where manufacturing fully electric investigation rigs more affordably becomes possible in the future.”

A satisfied customer is the foundation of everything

Geomachine’s strong foothold in the ground investigation industry is primarily thanks to its customers. “Without satisfied customers, we wouldn’t exist. The ground investigation industry is relatively small, and word-of-mouth travels far. Customers share a lot of information with each other and pass on their experiences about how well our products and services have met their needs.”

According to Juha Sandholm, the main reason for customer satisfaction is that Geomachine understands the primary goal of its customers’ operations. “Each of our customers wants to conduct their business in the most productive, profitable, and smart way possible. They feel that our products and services together form a package that enables this.”

Interested? Contact Geomachine!