Kategoriat

Geomachine Oy

In ground investigation rig procurement discussions, the features of the boom are among the most frequently asked topics. In this article, we explain the typical questions that tend to come up around booms.

“We’ve been developing booms for as long as Geomachine has existed,” begins Geomachine’s Sales Manager, Alex Lindholm. “Choosing the right boom is key to optimising a drilling rig’s performance and the success of the investigation—especially when operating in some of the world’s most challenging environments.”

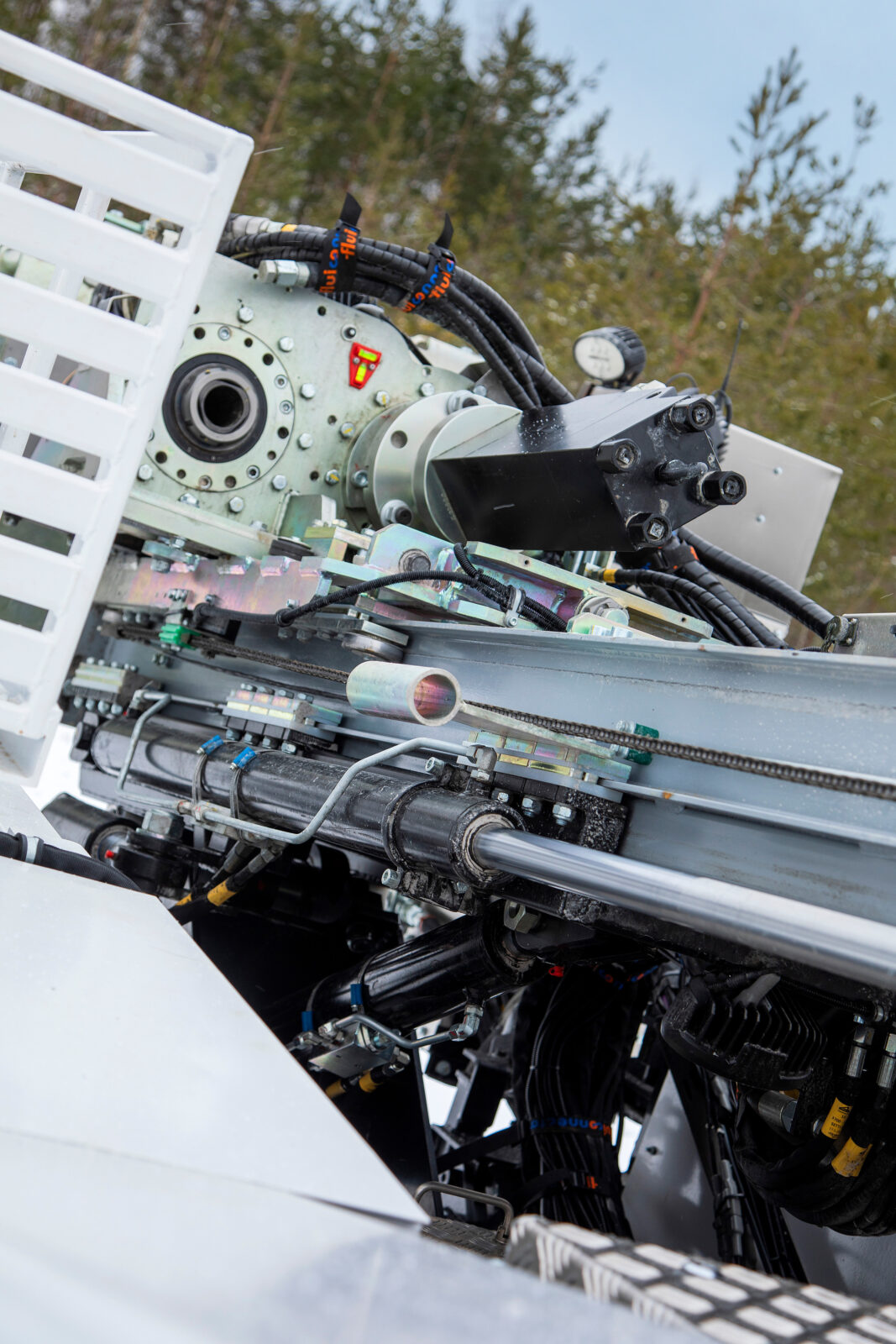

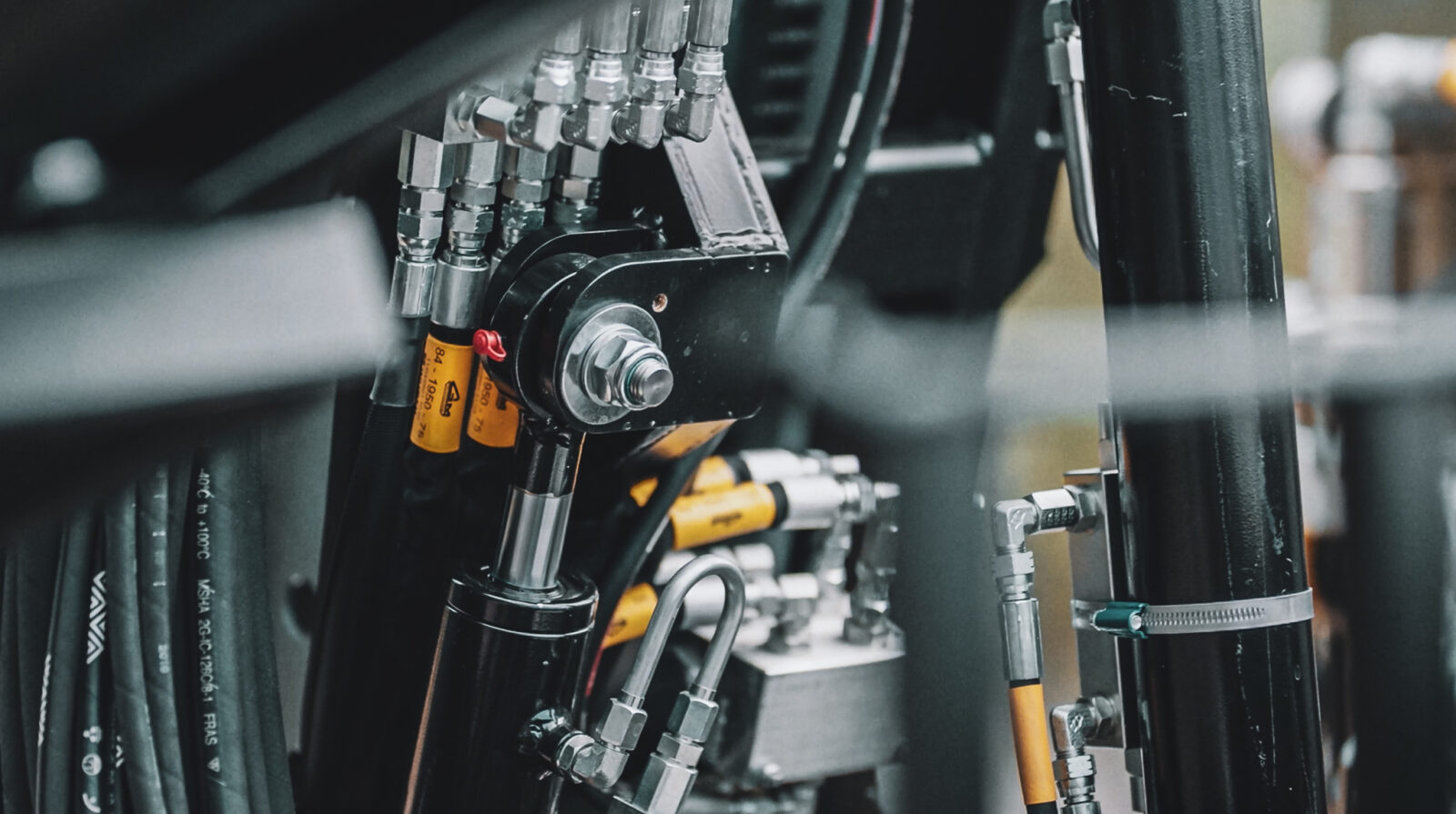

Geomachine booms are categorised according to their operating principle: direct feed, chain feed, and dual mast booms. Direct feed booms are designed for geotechnical and geological investigations as well as core sampling in rock. Chain feed booms are particularly suited to environments where boom height is restricted, such as rail works and tunnels. Geomachine’s range also includes a dual mast boom that combines the best features of both direct feed and chain feed systems.

Part of a rig package—or a standalone option

Most often, customers purchase the boom as part of a Geomachine rig package. “We offer rig models for every investigation method. By choosing the one that best suits their needs, customers can be confident that the boom included will also be suitable for their specific ground investigation methods.”

However, it’s also possible to buy a boom separately, without a rig platform—suitable, for example, for tractors, telehandlers or forestry machines. “If the customer already has a platform that performs well in a particular terrain, buying just the boom might be the right choice. The same applies if ground investigations are only needed occasionally, for instance as part of a broader groundworks business. In those cases, investing in just the boom can be a smart move.”

The most common questions

Customers usually ask three key questions about booms. “Just like with the full rig package, people want to know whether the boom will definitely work with their investigation methods. And yes—it absolutely will. We guarantee that each boom performs as intended in the method it was designed for. The second question typically concerns the boom’s weight, and the third is about compatibility with third-party platforms.”

Geomachine booms perform excellently when integrated into third-party platforms, provided that sufficient hydraulic output is available. “In practice, the platform just needs to be fitted with hydraulic hoses to connect the boom—and then it’s ready to go. For example, the GM75 boom mounted on a tractor can carry out the same investigations as the full GM75 rig package.”

However, a standard solution doesn’t always work seamlessly on a third-party platform. “If significant customisation is needed—for example, in mounting or if the platform can’t provide enough power—it may be wiser to consider purchasing a full rig package. Customisation takes time and parts, and those costs can add up. If the need for modifications is extensive, the full rig package may turn out to be the more cost-effective choice.”

What makes Geomachine booms so effective?

Alex Lindholm is occasionally asked what makes Geomachine booms so effective. “That’s probably my favourite question to answer. Since the beginning, our product development has always been based on genuine customer needs. Over the past 40 years, we’ve drilled deep into the realities of those working in the ground investigation field and have listened carefully to what they truly need on site. I can confidently say that this has allowed us to develop a boom range that meets the needs of the vast majority of users. And if our standard range doesn’t quite match the customer’s requirements, we’re open to customisation—if they’re willing to invest in it.”

Geomachine’s aim is to provide all its customers with products and services that offer concrete benefits and a competitive edge. “We promise our booms will deliver efficiency, reliability and confidence on site. They can also open up new business opportunities for companies whose core operations don’t currently include ground investigation or who haven’t previously offered these services.”

Interested? Contact Geomachine!

Geomachine Oy

When selecting a ground investigation rig, the first step is naturally to ensure that the new equipment is compatible with your investigation methods. But what other questions often arise during procurement discussions? That’s what we’ll explore in this article.

Geomachine currently offers a selection of seven different rigs, each designed for specific investigation methods. With such a wide range of options, it’s essential for ground investigation companies to have enough information to make the right purchasing decision.

Geomachine’s Sales Manager Alex Lindholm has helped numerous companies in the field select the most suitable and effective tools for their needs. A successful choice always stems from open dialogue. “Even if we’re dealing with a seasoned expert in the ground investigation industry, we never skip the step of mapping out the rig’s intended applications during procurement talks. It’s important to thoroughly assess the client’s current situation and make sure they’re aware of all the options that best meet their needs at this point in time.”

These three questions are the most common

Ground investigation is a highly specialised and relatively small field. For this reason, those working in the industry are usually well informed about the equipment options and manufacturers available. “A client who already knows us typically enters procurement talks with a specific machine model in mind. They may already have some experience with that model, making the discussion quite straightforward. However, even if the base machine is familiar, many are surprised to learn just how smart these rigs can be nowadays. That’s why we always take time to talk about how our digital services can now help optimise tasks such as machine maintenance, servicing, equipment management, and project planning.”

New clients often come with three standard questions. “They usually want to know whether the rig is compatible with their current method, whether it has enough power, and whether it can reach the necessary depths. These are easy questions to answer. All Geomachine rigs are absolutely capable of performing the methods they were designed for.”

The best choice now – but what about the future?

The ground investigation industry evolves alongside changes in its operational environment. According to Alex Lindholm, there is currently high demand for larger rigs that can be used for deep investigations. Market shifts often raise concerns among clients, and these are addressed during discussions. “No one can say for certain which investigation methods will be in highest demand in the future. The good news is that if you invest in a more robust rig now to meet current needs, it can often still be used for lighter methods as well. For instance, all our rig models can perform vane testing. This often comes as a surprise during discussions.”

When looking to the future, every client is also interested in how the machine will be maintained after the purchase. “We always talk about how future maintenance and spare part needs will be handled. With us, there’s no need for concern – our maintenance and support services are professional and readily available whenever needed. This part of our business is constantly evolving. A recent example is our new field service concept. We’ve recently doubled our field capacity, meaning that help is now available very quickly when needed.”

At the time of purchase, the client may not yet have a clear idea of which technical features would be ideal for the tool. “Sometimes clients only realise what features they want once they’ve started using the machine on an actual site. And that’s completely fine. During the next scheduled service, we can simply add the features the client wants.”

Brand loyalty built on preferences

User preferences also play a major role in choosing equipment. Once you get used to working with a particular brand and it proves reliable, brand loyalty tends to stick.

“It’s a bit like choosing a car. When a certain brand appeals to you for whatever reason, there’s little reason to switch. Those in the ground investigation industry who favour Geomachine rigs typically appreciate their durable build, easy mobility, smart features, and reliable maintenance and support. These are the practical reasons why they continue to choose our machines year after year.”

Interested? Contact Geomachine!

GeoUnion Oy

GeoUnion is a Finnish company specialising in ground investigation, surveying, and design services. It has relied on Geomachine’s drilling rigs for its ground investigations from the very start of its operations. There are many good reasons behind this long-standing partnership.

Founded in 1993, GeoUnion currently employs around 30 top professionals in the fields of surveying and geotechnics. CEO Markku Savolainen explains that one of the company’s core principles has always been to ensure that its employees have the best possible conditions for success. “Our company’s success is built on our people. From the outset, we decided that our growth wouldn’t be hindered by inadequate tools – and we chose Geomachine as our drilling rig supplier.”

GeoUnion currently operates seven Geomachine rigs, the latest of which was acquired in 2024. “Over the years, we’ve tried other brands, but we’ve found that Geomachine best suits our needs. We work in some of the world’s most challenging environments, and Finland’s dense moraine soils place high demands on drilling rigs. Geomachine’s machines are designed in Finland and perform reliably in our harsh and demanding conditions. That’s why they’re the best choice for us.”

Powerful performance and other outstanding features

GeoUnion’s fleet includes Geomachine drilling rig models GM25, GM75, and GM100. “The GM75 and GM100 are particularly well represented in our fleet. They are excellent multi-purpose machines, with power optimised for their size. They also perform exceptionally well in difficult and demanding terrain.”

However, according to Markku Savolainen, there is something even more important than power and terrain capability. “For us, safety is the number one priority. Geomachine’s machines meet safety requirements extremely well, for example through remote-control capability and excellent work lighting.”

Ground investigations are carried out to understand the conditions below the surface. “I really appreciate how Geomachine has invested in technology development in recent years. The GMTracker data-logger, for example, is an innovation that has clearly streamlined practical work and improved the quality of collected data. Best of all, Geomachine hasn’t just focused on technology but also on ensuring the tool is practical in real-world use. The data-logger doesn’t flinch at cold or outdoor working conditions.”

GeoUnion uses three different Geomachine rig models, and drillers switch between them depending on the investigation requirements. “Geomachine rigs have very similar functionality across models. This makes it much easier for drillers to adapt when switching tools.”

Electrification is part of the future of ground investigation

GeoUnion often takes part in public ground investigation tenders. According to Savolainen, the requirements set for contractors are clearly changing. “We’re seeing clear signs that in future, ground investigations will need to be carried out in a more emission-free and environmentally friendly manner. The minimum requirements for tenderers are becoming stricter and more diverse. We’re definitely heading towards a more electrified ground investigation industry.”

Environmental values are important to GeoUnion and its parent group, Solwers Plc – and these values translate into concrete action. “We calculate our carbon dioxide emissions annually and compare them to previous years. Until now, we’ve reduced emissions mainly through choices in our vehicle fleet, but going forward, we’ll have more opportunities to reduce emissions through our machinery as well. Last year we acquired a GM75 Hybrid, which now enables us to carry out electric ground investigations. We’re also closely monitoring how fully electric rigs are received on the market and how they perform on actual worksites. It’s clear that we must be able to meet the increasing environmental expectations of clients – and we want to ensure we’re fully prepared for that.”

On time, professionally, and competitively

GeoUnion aims to offer its clients the highest possible quality of service, based on three core promises. “We guarantee expert, customer-oriented service. Our clients can also trust that, conditions permitting, we always complete our work on schedule. In addition, we strive to be a competitive option and respond to requests for quotation with comparable pricing.”

GeoUnion continuously takes practical steps to deliver this excellent service experience. “We understand that success stems from customer satisfaction – and customer satisfaction is built on the success of our staff in delivering service. That’s why we invest heavily in ensuring our personnel always have the best tools for high-quality work. We keep our fleet up to date and provide regular training for our team.”

According to Markku Savolainen, Geomachine’s products are a great fit for any Nordic company operating in the geotechnical sector. “If you want an experienced and innovative manufacturer to support your business, with machines that operate efficiently and reliably in tough conditions, Geomachine is the right choice.”

Interested? Contact Geomachine!

Geomachine

Adopting digital tools for ground investigation is easy with Geomachine’s guidance. You don’t need to understand the technology or speak in complex terms. All you need to know is the direction in which you want to develop your operations.

“In the ground investigation industry, things have been done the same way for years, using familiar methods,” says Pasi Majakangas, who designs digital services for Geomachine. “Learning something new alongside your regular work can seem like a burden, so often, people prefer to stick with familiar practices. But what if embracing new solutions was made easy, and it turned out to be a smart and effortless investment from a business development perspective?”

Two ways to adopt

The core of Geomachine’s digital product family, the GMTracker data-logger, is automatically included with the purchase of a new machine. The data-logger can also be added to a machine already in use on-site.

Since digital tools are still relatively new in the ground investigation industry, discussions about their adoption are always led by the customer’s workflows, challenges, and needs, rather than product features. “Some of our customers know exactly what smart features they want from their new machine, and these are added to their GMTracker during the machine’s production phase. Other times, the customer might not have a clear vision of the best solutions for their specific operations. In those cases, we ask the right questions and determine the goals they have for the machine and their business development.”

The customer may also have identified pain points in their operations that they need solutions for. “If the areas that need improvement are already known, we focus on how our digital tools can help resolve these issues. If the goal is simply to get more out of their machines and processes, we’ll explain what’s possible with our digital services.”

Real-life examples

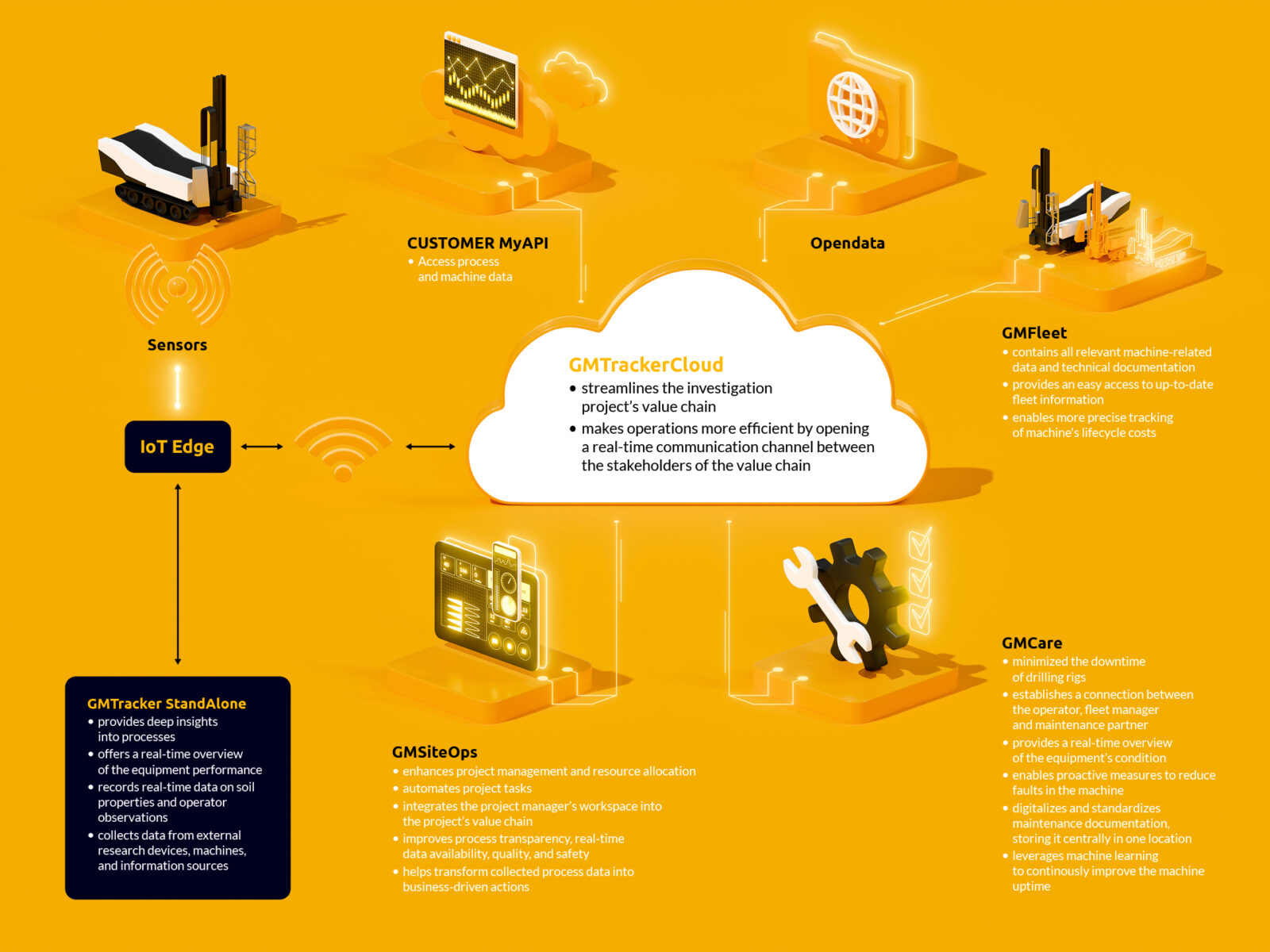

Pasi Majakangas shares that one issue may be long downtime due to maintenance queues, leading to slow and unprofitable project completion. “In such cases, we suggest adopting GMCare. It opens a two-way connection between the operator, machine maintenance manager, and service partner. The software gives the service partner a real-time view of the equipment’s condition, enabling preventive actions to reduce machine failures. GMCare also digitizes and standardizes maintenance documentation, storing it centrally in one place. The software uses machine learning to continuously build a knowledge base, making future machine maintenance more individualized and predictive.”

Another issue might be keeping the machine documentation up to date. “In that case, we suggest using GMFleet. This ensures all relevant equipment information is always available in real-time and kept up to date. GMFleet contains all the information related to the machine, including technical documentation and lifecycle data. It also provides easy access to information about the machine’s technical capabilities.”

A customer might also struggle with communication issues that slow down project progress. “In such cases, we recommend using GMSiteOps. It streamlines project management and resource allocation, automating related tasks. It digitalizes the project manager’s workspace and integrates it into the project’s value chain. GMSiteOps improves process transparency, real-time data, quality, and safety, while helping to transform the data collected from processes into business-driving actions.”

So, how to move forward?

If you’re interested in improving your business, the right place to start the conversation is with Geomachine’s Sales Manager, Alex Lindholm. “You can email or call Alex. He will arrange a meeting with you to review your business and needs. After the meeting, you’ll receive a proposal for the digital features that can help you reach your goals. If you’re integrating digital tools into an existing machine, the software installation will typically take 1–3 working days. It’s important to consider this when planning your project schedules.”

For those buying a new machine, the process is even easier. “Digital services are always offered with a new machine purchase, allowing you to share your operational optimization goals with our sales team. When the machine leaves the factory, it will already have all the intelligence you wanted pre-programmed.”

According to Pasi Majakangas, there’s no need to fear digital services. “Our product family is easy to understand and use, and our customers who already use the tools agree. If you want to boost your productivity and improve the quality of the data you collect, don’t hesitate to contact us. We’ll tell you which of our tools best suit your needs and how to get them up and running quickly.”

Interested? Contact Geomachine!

Geomachine

Geomachine aims to make ground investigation as efficient, profitable, and high-quality as possible. That’s why it develops cutting-edge digital innovations that will lead the industry into a new and smarter era.

Continuous development is deeply embedded in Geomachine’s DNA. In recent years, the company has focused particularly on digital innovations in its product development to enable companies in the ground investigation industry to conduct their business more intelligently and profitably.

“In the ground investigation industry, traditional methods have often been used, resulting in many manual workflows and fragmentation in the value chain,” says Pasi Majakangas, who designs digital services for Geomachine. “Four years ago, we initiated the development process for digital products with the aim of tackling these challenges.”

Geomachine’s digital product family currently includes four innovative tools. “The heart of our product family is the GMTracker data-logger. It is an extremely smart tool that provides full visibility into the investigation processes and gives an overview of the performance of the equipment used. In its StandAlone version, GMTracker works locally as an operator tool, and in its Cloud version, it creates a real-time, two-way connection between all project stakeholders. The Cloud version can also be extended with modules such as GMCare, which enhances machine maintenance and servicing, GMSiteOps for optimizing project management and planning, and GMFleet, the equipment registry.”

Step by step forward

As with all of Geomachine’s product development projects, the planning and development of the digital product family involved strong customer collaboration. “In the development of the GMTracker data-logger, we received invaluable support and insights from our long-time customer, Aluetaito Oy. They were involved in the project from the very beginning, and through iterative work, we developed the data-logger to the point where it could be launched to the market.”

The first version of the GMTracker data-logger was made for research methods used in Finland, and later versions were developed for Sweden and Norway. “From a product development perspective, the initial challenge was that there was considerable variation in the needs and practices of companies in the ground investigation industry. A single software solution for everyone was not an option at that point, so the product had to be configured individually for each customer’s specific needs. We focused heavily on customization in our product development. Today, customizing GMTrackerCloud to meet the unique needs of customers can be done with just a few clicks.”

Once the first version of GMTracker and its project management features were up and running, the product development moved forward. “In the next phase, we began considering solutions to enhance machine maintenance and servicing and improve equipment management transparency. These challenges were addressed with the development of the GMCare and GMFleet tools.”

Toolbox expands as needed

According to Pasi Majakangas, no other digital product family like Geomachine’s is currently available on the market. “Until now, individual tools could be purchased from various providers. However, this has resulted in customers having to manage a system architecture that could become messy and difficult to handle. Each program had to be learned separately, and integrating them could require a lot of effort. Managing the whole is now much smarter and easier when all the essential tools can be obtained from one provider.”

One of the strengths of Geomachine’s digital product family is its scalability. “Our products adapt to the needs of the user. You don’t have to purchase the entire extensive toolbox at once; it can be expanded as needed.”

Once all the innovative features of GMTrackerCloud are activated, it provides solutions for the efficient and data-driven execution of the key tasks in ground investigation projects. The transparency of supply chains immediately increases project efficiency, reduces equipment downtime, improves fleet management, and reduces the amount of manual, unnecessary work. In the long term, projects become more productive continuously, as machine learning makes maintenance and servicing operations more predictive. Data on operations and equipment performance constantly increases, helping to make the overall operation more profitable over time.

Continuously smarter and more versatile

Pasi Majakangas says that the development of the digital product family is still ongoing. “In the future, our product family will include even more analytics and 3D visualization features. With these, for example, risk assessments and quality assurance on work sites will be done even more efficiently. The drill rig will learn to identify ground characteristics and automatically suggest them to the driller. Additionally, it will take care of its own maintenance and identify its own issues. This way, maintenance can be performed as soon as the machine starts to show signs of failure, even before an actual breakdown occurs.”

Geomachine’s digital tools are currently in use by leading companies in the ground investigation industry in Finland, Sweden, Norway, and Iceland. “Every ground investigation company that understands that project productivity requires transparency across the value chain can benefit from our innovations. We want to enable our customers to focus on the right things. Do more with less – that’s what we want to offer our customers in a nutshell.”

Interested? Contact Geomachine!

Geomachine

Updating the equipment used in geotechnical investigations becomes relevant for every industry player from time to time. Whether it’s a facelift or a complete renewal, the process is clear and seamless under Geomachine’s guidance.

“The geotechnical investigation industry in the Nordic region is relatively small,” begins Alexander Packalén, Geomachine’s Chief Operating Officer. “It’s a highly specialized field where industry professionals often know each other. That’s why the companies reaching out to us for their equipment needs are frequently already familiar to us.”

Regardless of whether the customer is a long-time partner or a new acquaintance, the discussion always starts by aligning with their needs. “Most of our customers are well-informed and have a clear idea—down to the model—of the machine that best suits their requirements. However, sometimes they only have a general idea of the intended use. In such cases, we explore the situation in more detail, and based on these discussions, we determine the best approach for moving forward with the procurement process.”

The needs of all stakeholders are considered

When a customer first contacts Geomachine about acquiring a machine, their primary concern is usually the cost. “When the time comes to make a purchase, it’s naturally important to understand the budget scale. Once the investment range is clear, the customer can proceed with internal decision-making within their organization.”

The next step involves diving into the details. “We arrange a meeting for a thorough needs assessment. In addition to the decision-maker, we also welcome the machine operators to this discussion. A skilled driller typically has a strong opinion on the features their tool must have. By mapping out these requirements during the design phase, we can ensure a cost-effective production process, avoiding unnecessary modifications later when the machine is already nearing completion.”

Should you upgrade or replace?

According to Alexander Packalén, the goal is always to find the best solution tailored to each customer’s needs. “We provide calculations for our customers to assess whether upgrading their existing equipment or investing in a new machine would be more cost-effective in their specific case. This analysis is especially crucial for companies continuously striving for better profitability.

Sometimes, an upgrade isn’t enough. Companies positioning themselves as industry pioneers and preparing for future changes in their business environment often choose to acquire an entirely new machine. “The geotechnical investigation industry is subject to increasingly stringent regulations, particularly regarding emissions standards. If a company aims to operate in densely built urban areas or participate in public tenders, acquiring a new machine is often the smartest choice. Even if an old machine has been upgraded with smart technology, a new boom, or other modern features, it won’t be competitive if its diesel engine exceeds emission limits.”

The geotechnical investigation sector is constantly evolving. “We closely monitor industry developments and regulatory changes. While no one can predict the future with certainty, we can at least provide well-informed insights based on our expertise.”

Start the conversation when the need arises

When it’s time to update or renew equipment, Alexander Packalén encourages reaching out to Geomachine without hesitation. “Our Sales Manager, Alex Lindholm, is the right person to contact by phone or email. He initiates the discussions and assembles the Geomachine team to drive the procurement process forward. Depending on the case, machine production times range from a few months to a year. That’s why it’s best to start the conversation as soon as a new purchase is on the horizon—ensuring that the machine is ready for use exactly when needed.”

Regardless of the level of preparedness or prior knowledge about equipment procurement, Geomachine is always a valuable partner. “We have been in the geotechnical investigation field for several decades and have learned to listen closely to our customers’ needs. We guide the procurement process in close collaboration with our clients, from the initial needs assessment to the moment the machine rolls off our production line. Customer satisfaction is always our priority, and we are known for this in the industry. That’s why we are the right partner for professionals who want to work with the best tools on the market and continuously improve their business success.”

Interested? Contact Geomachine!