Kategoriat

Geomachine

Geomachine’s range of drilling rigs covers all the needs of ground investigation. The fleet currently includes seven versatile rigs designed for various levels of challenging investigations. Each rig is packed with superior technical features, usability, and intelligence.

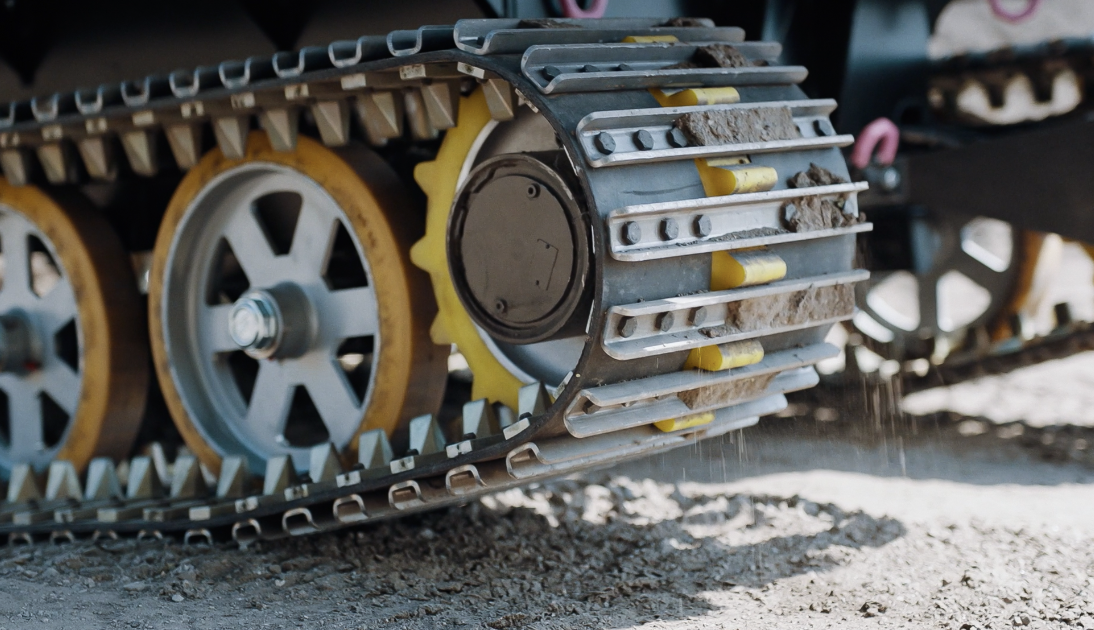

The smallest rig in Geomachine’s product family is the two-ton GM50, which can be transported on a car trailer. The flagship model is the eight-wheeled GM8 mammoth, capable of traversing even the most difficult terrains with low ground pressure. The core of the machine lineup consists of the GM75, GM85, and GM100, multi-purpose machines highly valued by ground investigation professionals.

All Geomachine drilling rigs are designed and manufactured in Finland. Each rig operates flawlessly in varying soil conditions, challenging terrains, as well as in snowy and harsh weather. The largest geotechnical drilling rigs are also excellently suited for geological investigations when equipped with diamond drilling equipment.

Modularity brings customization

All Geomachine drilling rigs are modular. This ensures that customers always have access to the most suitable tool without expensive customization costs or long delivery times.

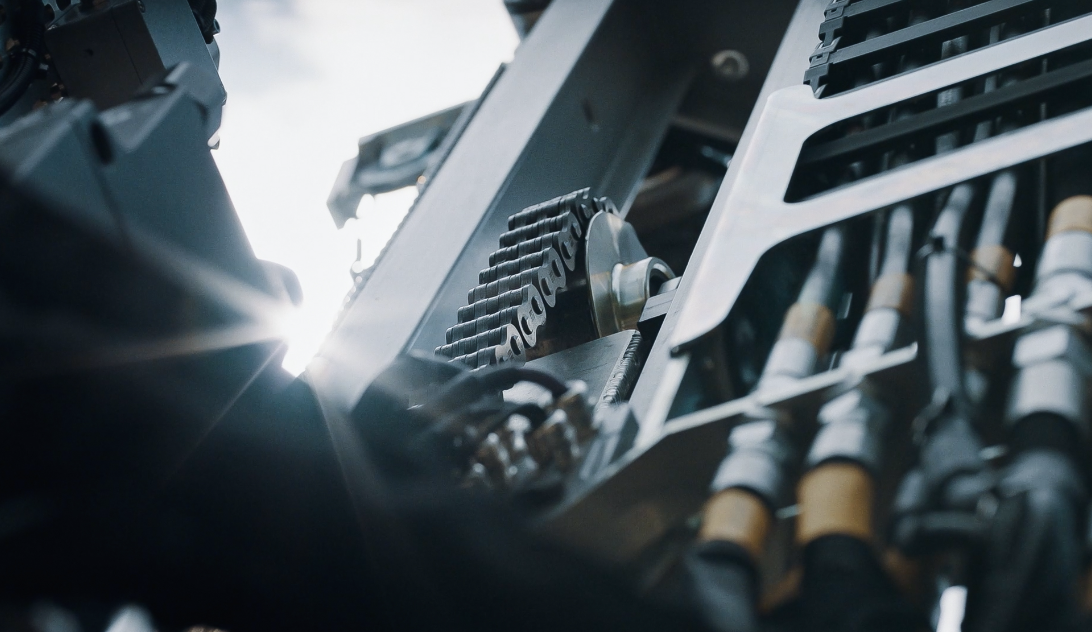

In practice, modularity means that the machine base can be equipped with the most suitable boom. The boom range includes several innovative and durable options and can be categorized based on their operating principles into direct feed, chain feed, and dual mast booms. All boom types can also be installed on platforms other than Geomachine’s own, provided they have sufficient hydraulic output. In addition to drilling rigs, they are also suitable for tractors, excavators, and barges.

An essential part of the machines’ modularity is the dual drill table in Geomachine’s booms, which can be equipped with drilling and investigation equipment tailored to the user’s needs.

The power source of the machine can also be selected according to needs. For those prioritizing zero emissions and quiet operation, an electric motor package is the right choice. The diesel engines used in Geomachine’s drilling rigs meet the strictest Stage 5 emission standards and can be operated with renewable diesel.

Most valued features

Geomachine’s products are always developed to serve genuine customer needs. Year after year, customers highly value ergonomics, usability, and safety in operations. Therefore, these features are always standard in all Geomachine ground investigation rigs.

A crucial factor affecting work ergonomics is the control panel positioned at the right height. Geomachine’s machine control panels have multi-directional adjustability, allowing the panel to be set at an optimal height even on uneven terrain.

Usability is further enhanced by the fact that all machine models today have very similar operational functions. This means that once the operating principle of a tool is learned, it doesn’t need to be relearned when switching machine models.

Safety features in Geomachine’s machines are also at a high level. Work safety is improved by features such as remote control enabled by the electronic IQAN control system and a separate rod-changing area.

Intelligent working

The ground investigation business follows the same principles as business in general. The ultimate goal is always to operate as qualitatively, productively, and profitably as possible. The investigation process itself is quite standardized today. The most productive detail for the entire process is how qualitatively the investigation data can be captured and how diversely it can be utilized.

Geomachine stands out from its competitors with the intelligence of its products. When all of Geomachine’s digital services are activated, the operator is equipped to efficiently and data-drivenly perform the most critical key tasks of all investigation projects.

Project profitability improves immediately as supply chains become transparent, equipment downtime decreases, equipment management improves, and unnecessary manual work becomes a thing of the past for all members in the project’s value chain. In the long term, project productivity further increases because, thanks to machine learning, investigation work as well as machine maintenance and servicing become more predictive. As the knowledge base on operations and equipment performance diversifies, it helps make the overall operation increasingly profitable.

Uncompromising quality for frontline professionals

Geomachine’s products and services are the right choice for industry operators who are not satisfied with merely completing the work but aim to conduct investigations more intelligently and with higher quality continuously. This means that only top-class tools are acceptable, and they must also be ready to meet future challenges. In the future, those who understand the importance of seamlessness in the project members’ value chain will also succeed.

Geomachine aims to help all its customers excel in their work in the best possible way. This is achieved by taking the ground investigation industry to a new, smarter, and more productive era.

Interested? Contact Geomachine!

Geomachine

Updating the equipment used in geotechnical investigations becomes relevant for every industry player from time to time. Whether it’s a facelift or a complete renewal, the process is clear and seamless under Geomachine’s guidance.

“The geotechnical investigation industry in the Nordic region is relatively small,” begins Alexander Packalén, Geomachine’s Chief Operating Officer. “It’s a highly specialized field where industry professionals often know each other. That’s why the companies reaching out to us for their equipment needs are frequently already familiar to us.”

Regardless of whether the customer is a long-time partner or a new acquaintance, the discussion always starts by aligning with their needs. “Most of our customers are well-informed and have a clear idea—down to the model—of the machine that best suits their requirements. However, sometimes they only have a general idea of the intended use. In such cases, we explore the situation in more detail, and based on these discussions, we determine the best approach for moving forward with the procurement process.”

The needs of all stakeholders are considered

When a customer first contacts Geomachine about acquiring a machine, their primary concern is usually the cost. “When the time comes to make a purchase, it’s naturally important to understand the budget scale. Once the investment range is clear, the customer can proceed with internal decision-making within their organization.”

The next step involves diving into the details. “We arrange a meeting for a thorough needs assessment. In addition to the decision-maker, we also welcome the machine operators to this discussion. A skilled driller typically has a strong opinion on the features their tool must have. By mapping out these requirements during the design phase, we can ensure a cost-effective production process, avoiding unnecessary modifications later when the machine is already nearing completion.”

Should you upgrade or replace?

According to Alexander Packalén, the goal is always to find the best solution tailored to each customer’s needs. “We provide calculations for our customers to assess whether upgrading their existing equipment or investing in a new machine would be more cost-effective in their specific case. This analysis is especially crucial for companies continuously striving for better profitability.

Sometimes, an upgrade isn’t enough. Companies positioning themselves as industry pioneers and preparing for future changes in their business environment often choose to acquire an entirely new machine. “The geotechnical investigation industry is subject to increasingly stringent regulations, particularly regarding emissions standards. If a company aims to operate in densely built urban areas or participate in public tenders, acquiring a new machine is often the smartest choice. Even if an old machine has been upgraded with smart technology, a new boom, or other modern features, it won’t be competitive if its diesel engine exceeds emission limits.”

The geotechnical investigation sector is constantly evolving. “We closely monitor industry developments and regulatory changes. While no one can predict the future with certainty, we can at least provide well-informed insights based on our expertise.”

Start the conversation when the need arises

When it’s time to update or renew equipment, Alexander Packalén encourages reaching out to Geomachine without hesitation. “Our Sales Manager, Alex Lindholm, is the right person to contact by phone or email. He initiates the discussions and assembles the Geomachine team to drive the procurement process forward. Depending on the case, machine production times range from a few months to a year. That’s why it’s best to start the conversation as soon as a new purchase is on the horizon—ensuring that the machine is ready for use exactly when needed.”

Regardless of the level of preparedness or prior knowledge about equipment procurement, Geomachine is always a valuable partner. “We have been in the geotechnical investigation field for several decades and have learned to listen closely to our customers’ needs. We guide the procurement process in close collaboration with our clients, from the initial needs assessment to the moment the machine rolls off our production line. Customer satisfaction is always our priority, and we are known for this in the industry. That’s why we are the right partner for professionals who want to work with the best tools on the market and continuously improve their business success.”

Interested? Contact Geomachine!

Geomachine

The emission class requirements for machines used in ground investigation are becoming increasingly stringent, and the pressure to work in an environmentally friendly manner is growing. Geomachine’s response to this challenge is the fully electric GMe100 drill rig.

The emissions of diesel-powered work machines have begun to be restricted, especially in densely built urban areas. For example, in Oslo, their use is no longer permitted. Efforts to reduce emissions are also evident in public tenders organized by cities, where emission class requirements are stricter than before, even if emissions are not yet legally regulated in the tendering area.

In the world of ground investigation, just like in technological development in general today, the trend is towards electrification. New product innovations are continually being introduced under this theme. Geomachine is also actively developing products to meet changes and expectations in its operating environment. The latest example of this is the fully electric GMe100 ground investigation rig.

New product innovations are created in collaboration with customers

Geomachine’s Chief Technology Officer, Vesa-Matti Salminen, explains that the GMe100 ground investigation rig was developed based on market needs. “When the requirement for zero-emission operation was enforced in Oslo, Norway, our distributor operating there contacted us. Following discussions and market research, we began developing an electrically powered drill rig in 2023.”

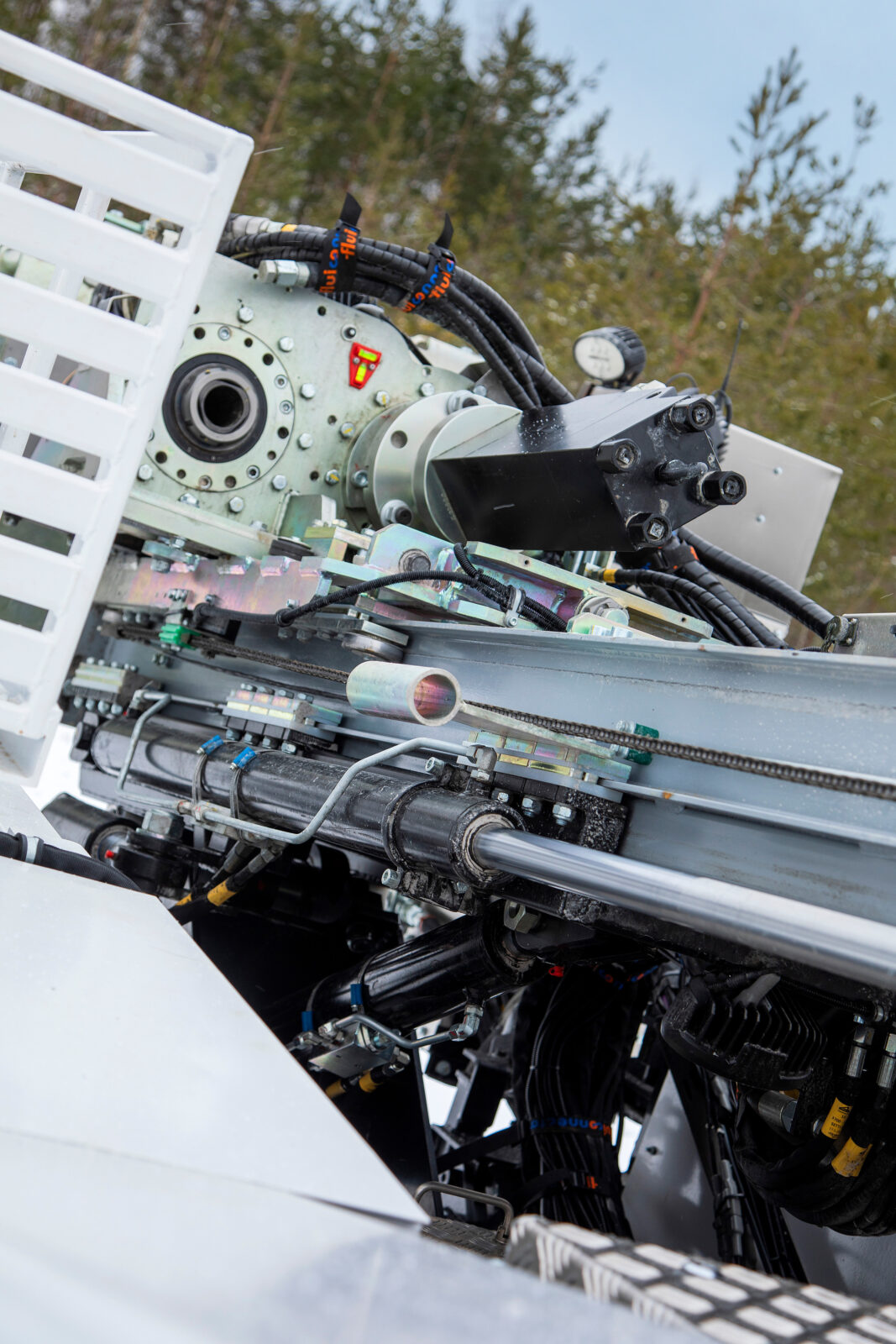

The GMe100 drill rig was built on the existing diesel-powered GM100 platform. It retains the same functionalities and usability as its diesel-powered twin. The machine’s operations remain hydraulic, but power generation in this rig is fully electric.

The length of Geomachine’s product development process varies depending on whether it involves a completely new product innovation or the further development of an existing product. The journey of the GMe100 drill rig from the drawing board to machine delivery took about two years.

When developing a completely new innovation, the product development process does not end at the time of delivery. “Although the machine is ready at delivery, close collaboration with the customer continues in the support phase,” says Geomachine’s Head of Engineering, Juha Sandholm. “We collect customer feedback on the real-world functionality of the machine to make further refinements if needed. Customers who invest in new innovations are industry pioneers. They understand that a finished product can still be refined after deployment and are keen to participate in this stage of product development.”

An electrically powered option for ground investigation

The GMe100 ground investigation rig is suitable for all the same investigation methods as its diesel-powered twin. These include dynamic probing, weight sounding, percussion drilling, casing drilling, spt and dspt testing, cpt and cpt-u testing, and pore pressure drilling. Additionally, it is suitable for groundwater pipe installation and sampling from both hard and soft grounds.

The GMe100 rig is powered by a battery-operated electric motor. Compressed air is supplied via an electric compressor. “During product development, we realized that using an electric compressor improves the efficiency of the fully electric machine, allowing for longer operation on a single battery charge,” says Juha Sandholm. “With a dedicated motor for the compressor, we were able to reduce the size of the machine’s main powertrain motor.”

The battery life of the rig varies depending on the investigation method used, and its capacity can be increased with an additional battery pack if necessary.

Like Geomachine’s equipment in general, the GMe100 is highly intelligent. It features an IQAN control system and GMTracker data logging software. A Cloud version of the logging software is also available, enhancing workflow efficiency, machine maintenance, and project management by connecting all stakeholders in the project’s value chain in real time.

Usability was another key focus in designing the GMe100 rig. This machine includes more storage space than before for the operator’s tools and essential liquids.

Key principles of product development

Vesa-Matti Salminen explains that Geomachine adheres to specific requirements in product development, ensuring that every product meets the highest standards. “We strive for quality in everything we do; our machines must be durable and perform at their best. Our products must also be easy to use. That’s why we aim for minimal differences in usability between models. Workplace safety is another crucial factor, and we continuously develop new solutions to enhance it.”

Geomachine’s customers share a commitment to working with the most reliable and user-friendly machines on the market. But that’s not all. “Our customers also highly value efficient and high-quality customer support. It’s important for them to get assistance from a familiar service representative who knows the machine’s history and features inside out.”

The GMe100 is a product innovation that Geomachine is extremely proud of. “Drawing on our extensive experience, we have successfully built a machine that enables ground investigation with exceptional quality and efficiency—now also in a more environmentally friendly and emission-free manner, meeting today’s demands.”

Interested? Contact Geomachine!

GMTracker

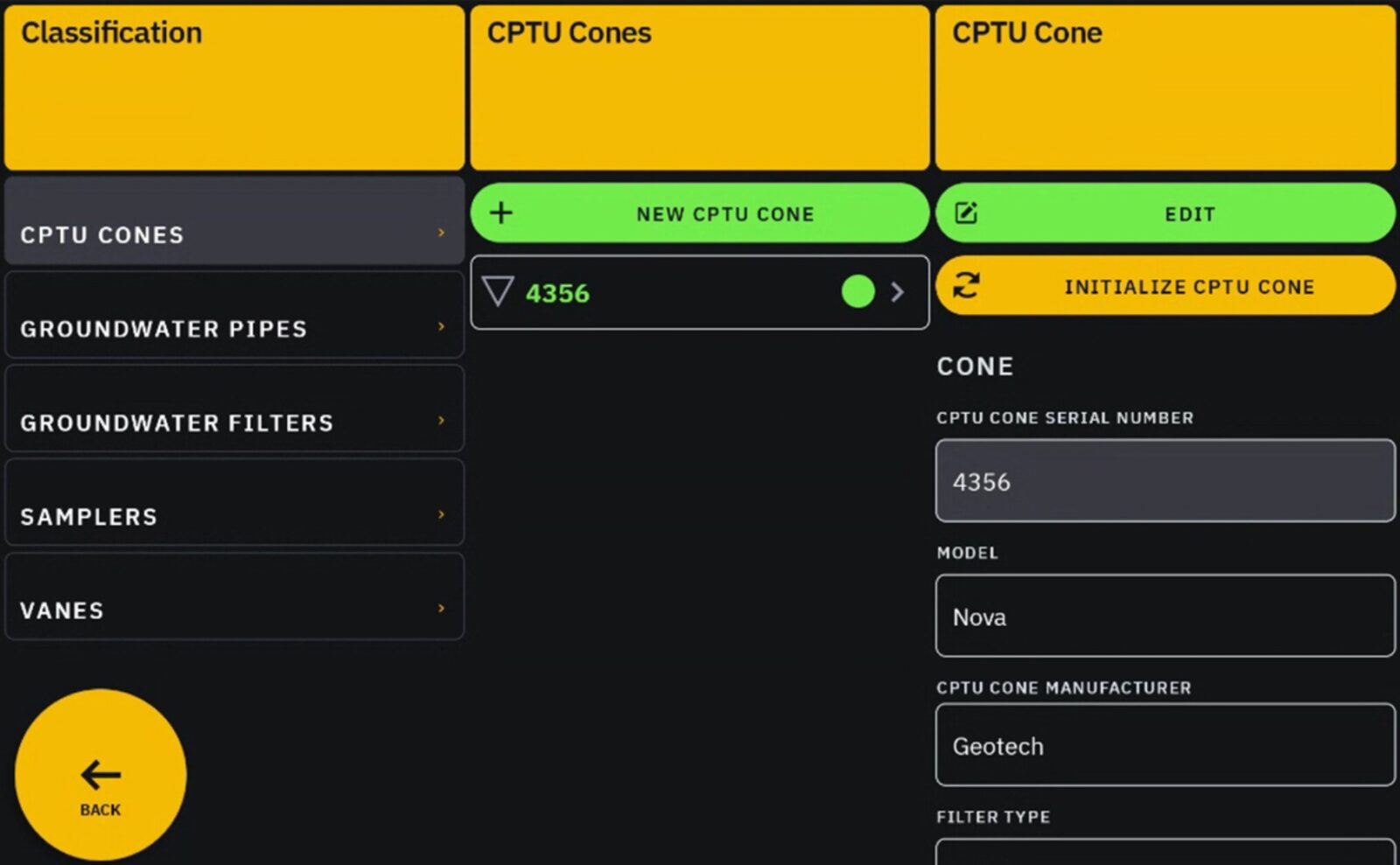

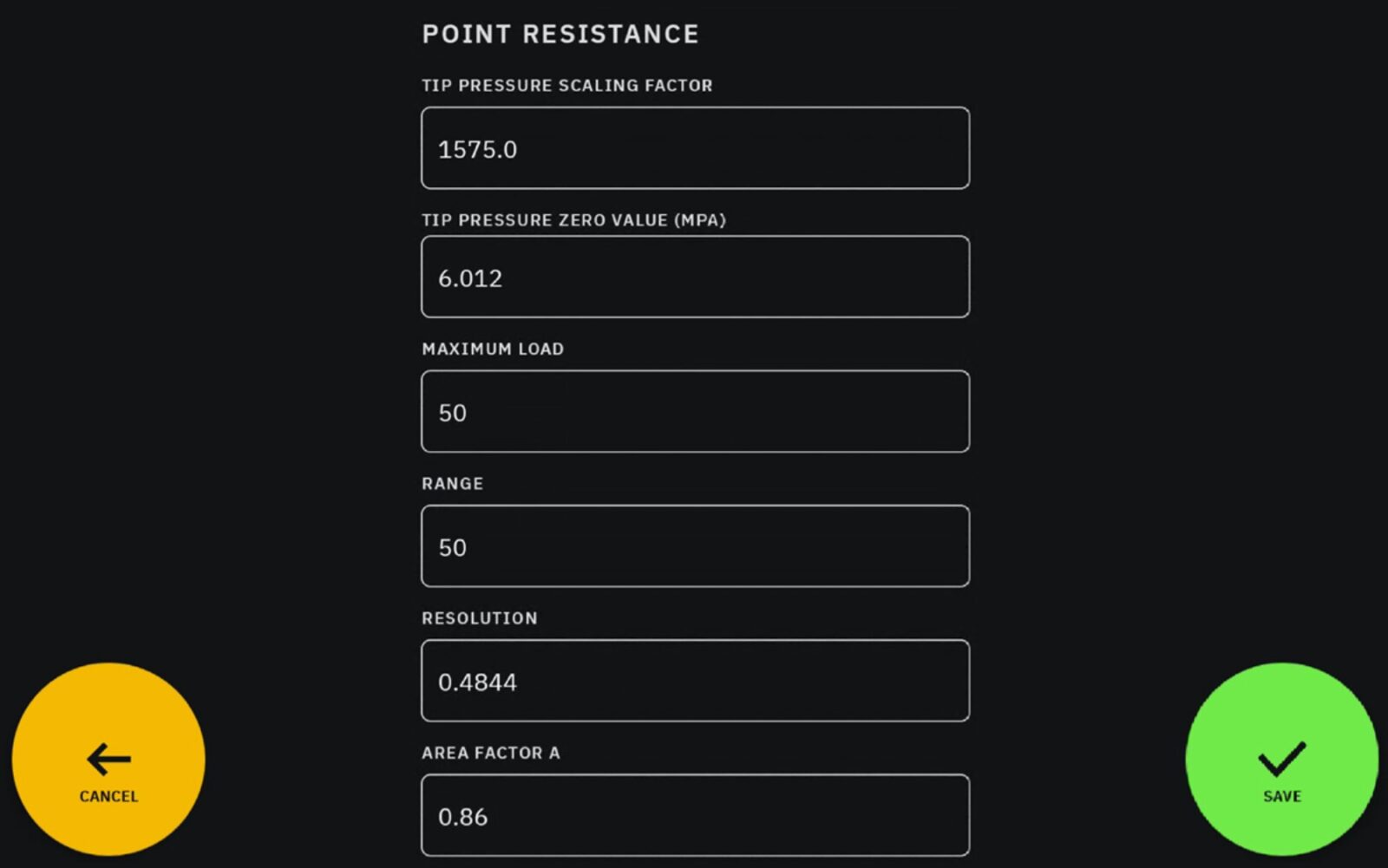

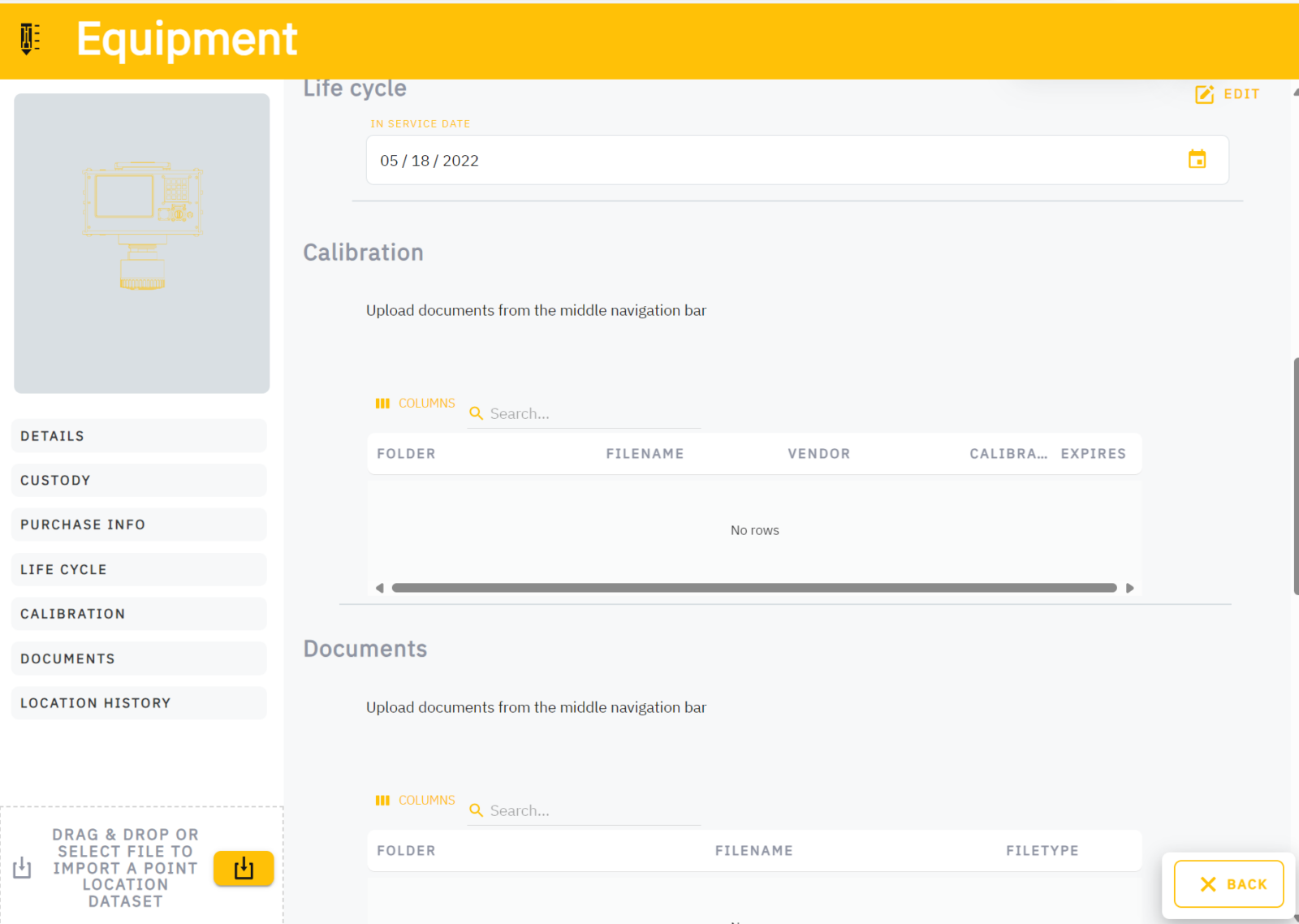

Information about the geotechnical field equipment used in ground investigations must be documented in the investigation report. Thanks to a new feature in the GMTracker data-logger, data on equipment is now transferred to the investigation report without manual effort.

The equipment required for ground investigations include, for example, CPT cones, vane shear devices, and sampling tools. These details must also be recorded in the work report for the investigation.

The new feature added to the GMTracker data-logger enables the maintenance and automatic adding of equipment data in work reports. The equipment registry contains information on the device’s identifier, model, type, and calibration, depending on the device. GMTracker is the only data-logger on the market whose registry also includes sampling tubes. Thanks to this new feature, equipment data is always accurately recorded in reports.

In the future, equipment management will also be integrated into the Cloud version of the GMTracker data-logger. Once data can be stored in the cloud, all stakeholders requiring equipment information will gain a comprehensive view of the devices used by the investigation company, their age, condition, and calibration status.

Managing specialized equipment through GMTrackerCloud will not only enhance reporting but also streamline the execution of investigation projects. It will help project management allocate sampling tasks to specific investigation vehicles without needing to transfer equipment from other sites. In the future, calibration values for equipment will also be manageable via GMTrackerCloud.

Interested? Take contact!

GMTracker

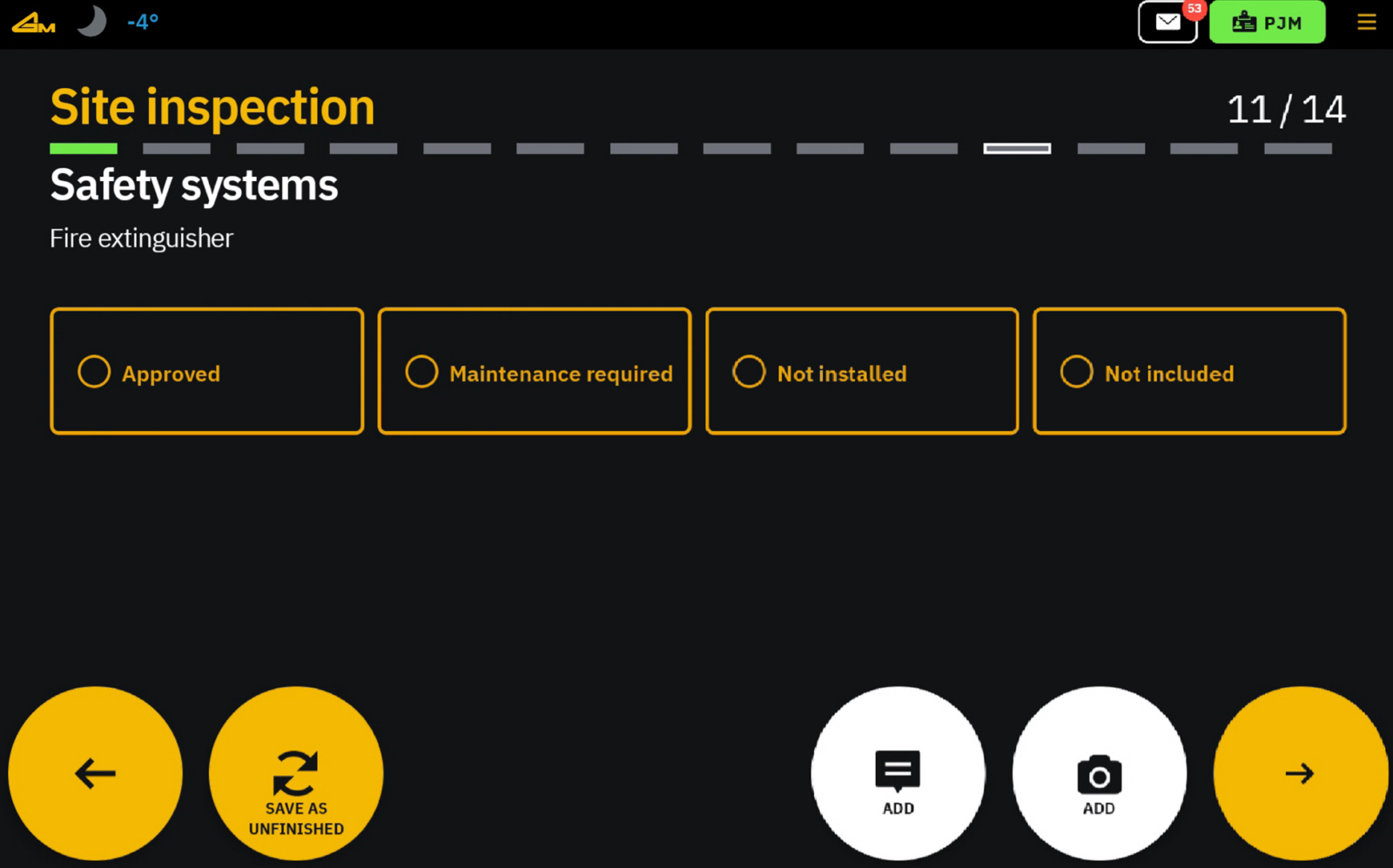

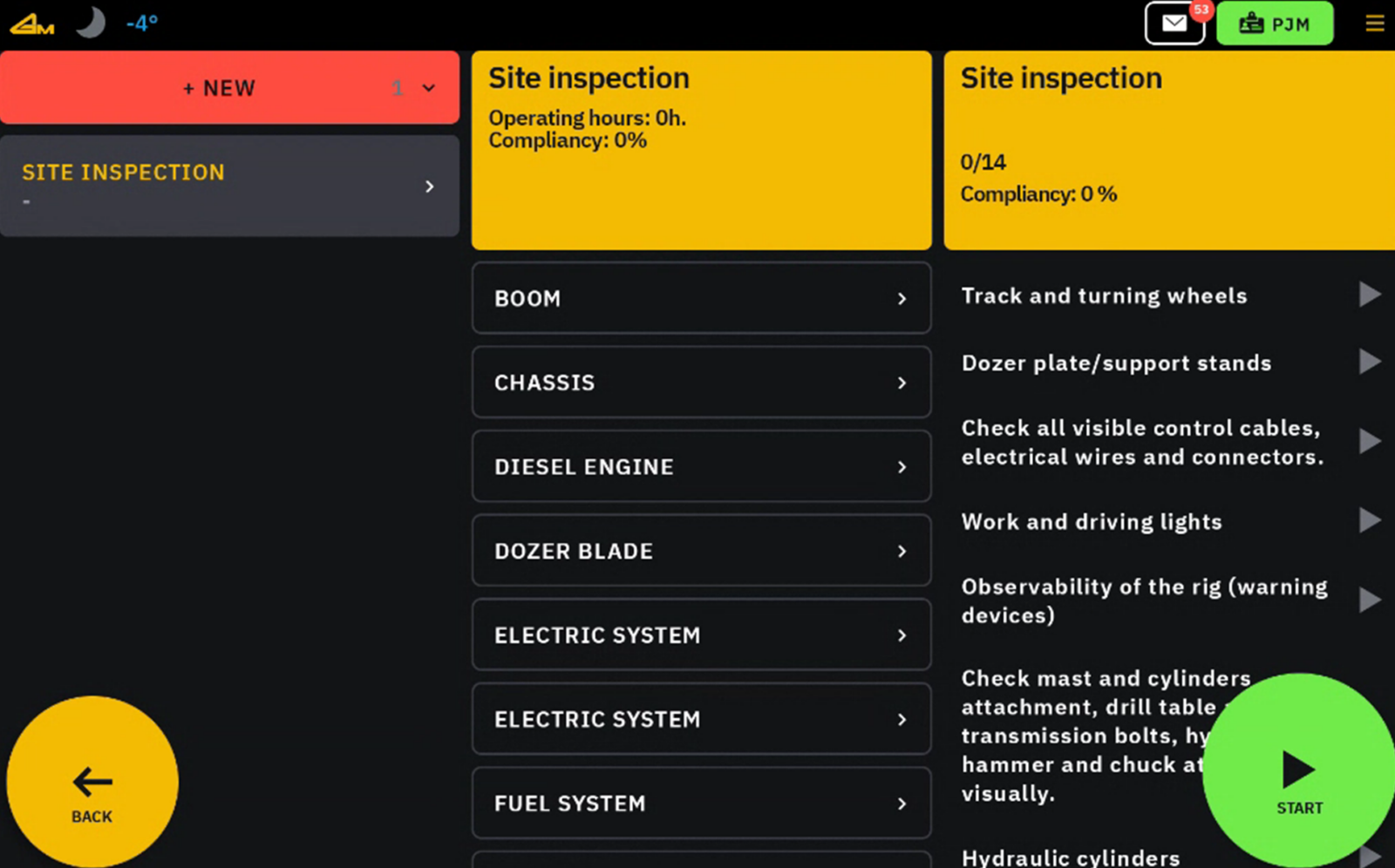

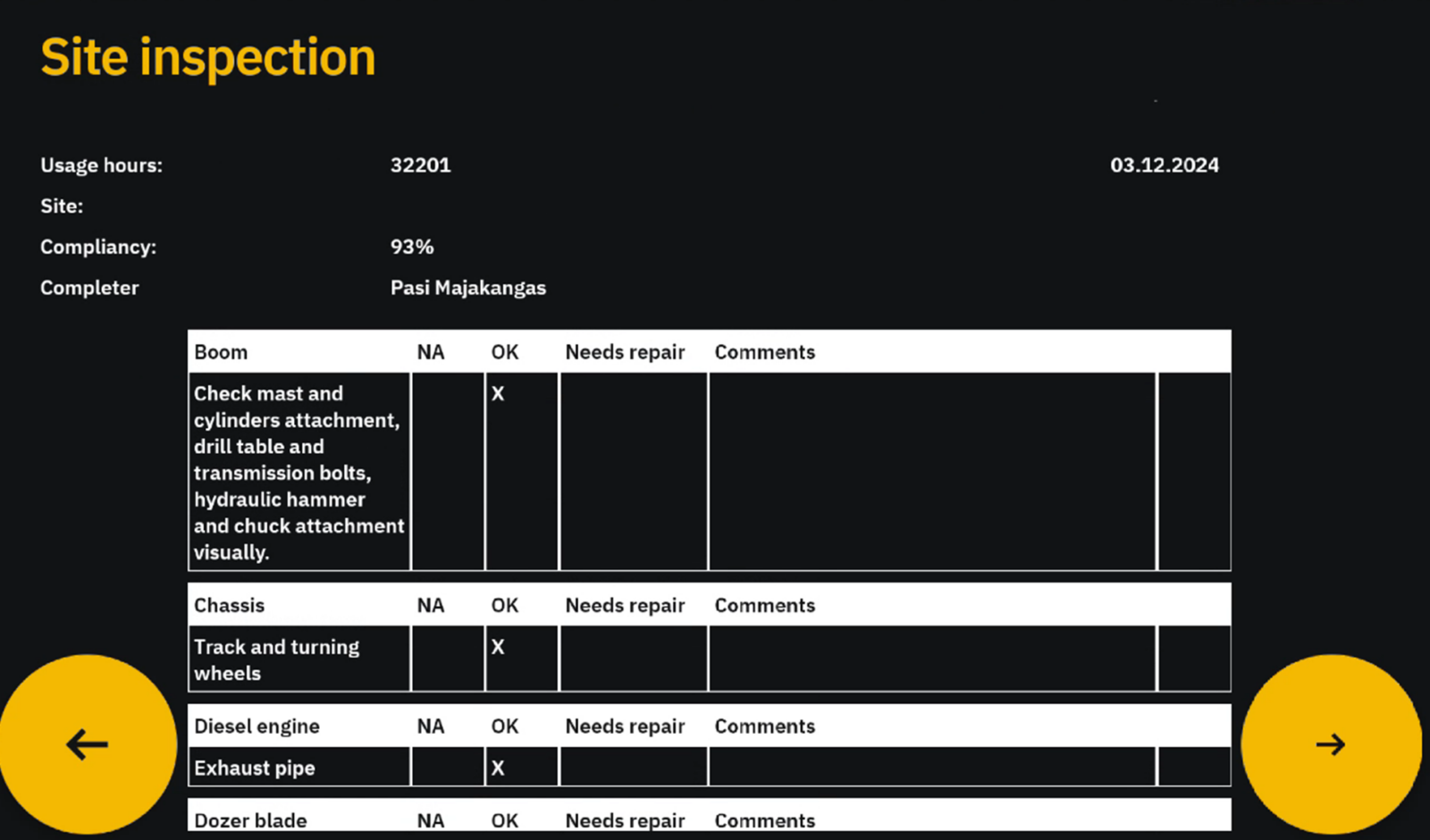

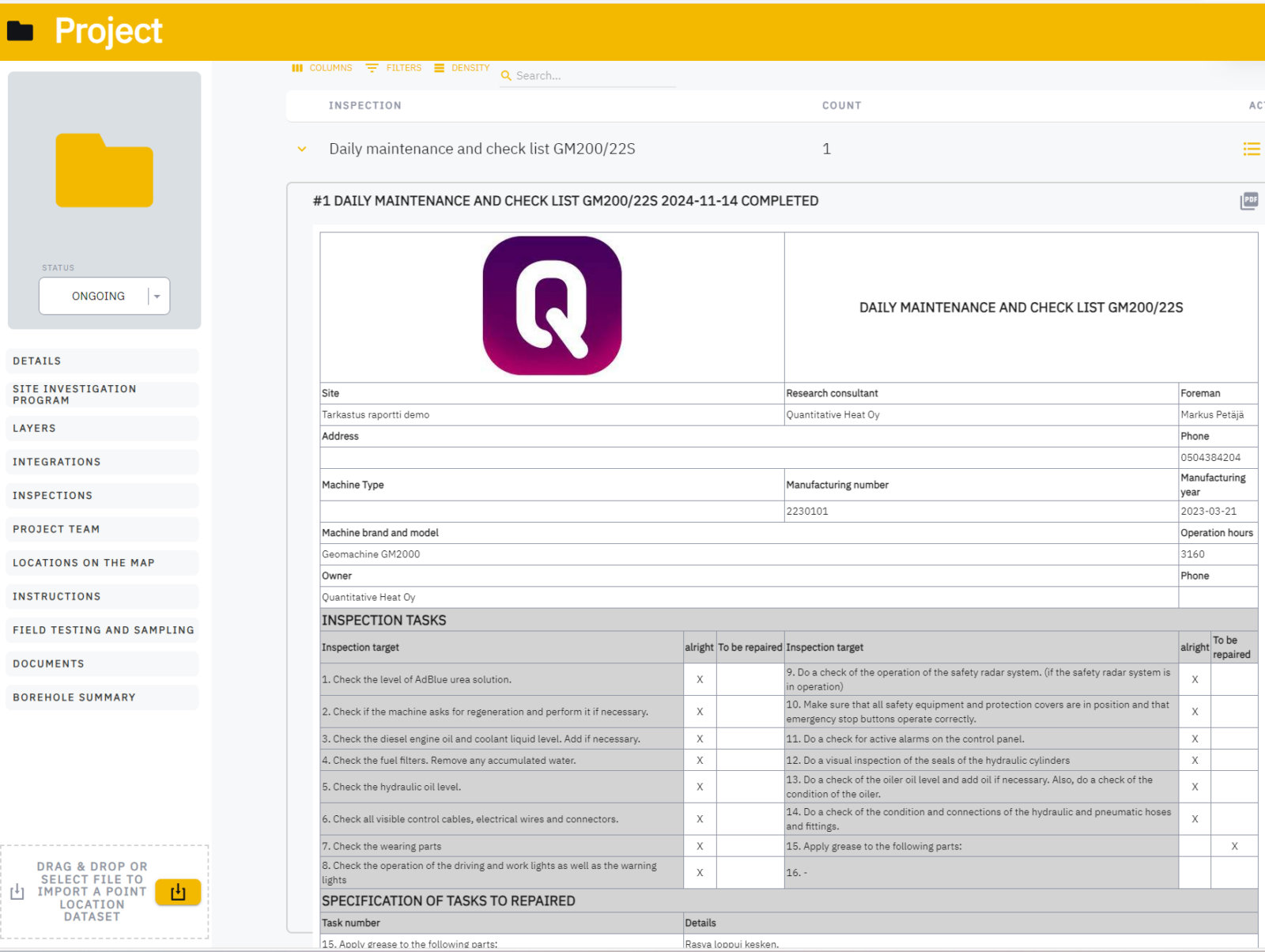

A new intelligent feature has been added to the GMTracker data-logger’s Cloud-version. The digital safety inspection streamlines the process of ensuring occupational safety measures are met, making it easier to comply with safety and quality requirements.

Before starting a soil investigation or well-drilling work, a commissioning inspection must be performed on the drilling rig at the site. For longer-term projects, daily or weekly inspections are also required. The GMTracker data-logger now serves as a tool to efficiently carry out these procedures as well.

Thanks to the new feature in the GMTracker data-logger, the safety inspection process can now be conducted in a standardized, digital format, eliminating time-consuming paperwork. The Cloud version of the data-logger enables real-time reporting of inspection results and any detected discrepancies to all relevant stakeholders. This feature ensures that the inspection history of the equipment, including records of any failed inspection tasks, is securely stored. Inspection task lists are fully customizable to meet user needs.

By digitizing site inspections, Geomachine emphasizes that working safety is just as important as its efficiency, quality, and environmental sustainability. This feature aims to familiarize operators with safe work practices and integrate risk assessment into routine operations. It also ensures that information about working conditions and the safe operational status of machines is always accessible to external inspectors, such as authorities, when required.

International standards ISO9001 and ISO14001 require Geomachine to operate in accordance with the highest quality standards. However, our aim is not only to meet these requirements but also to exceed them whenever possible. Adding the digital safety inspection feature to the GMTracker data-logger is one example of this commitment.

Interested? Contact us!

GMTracker

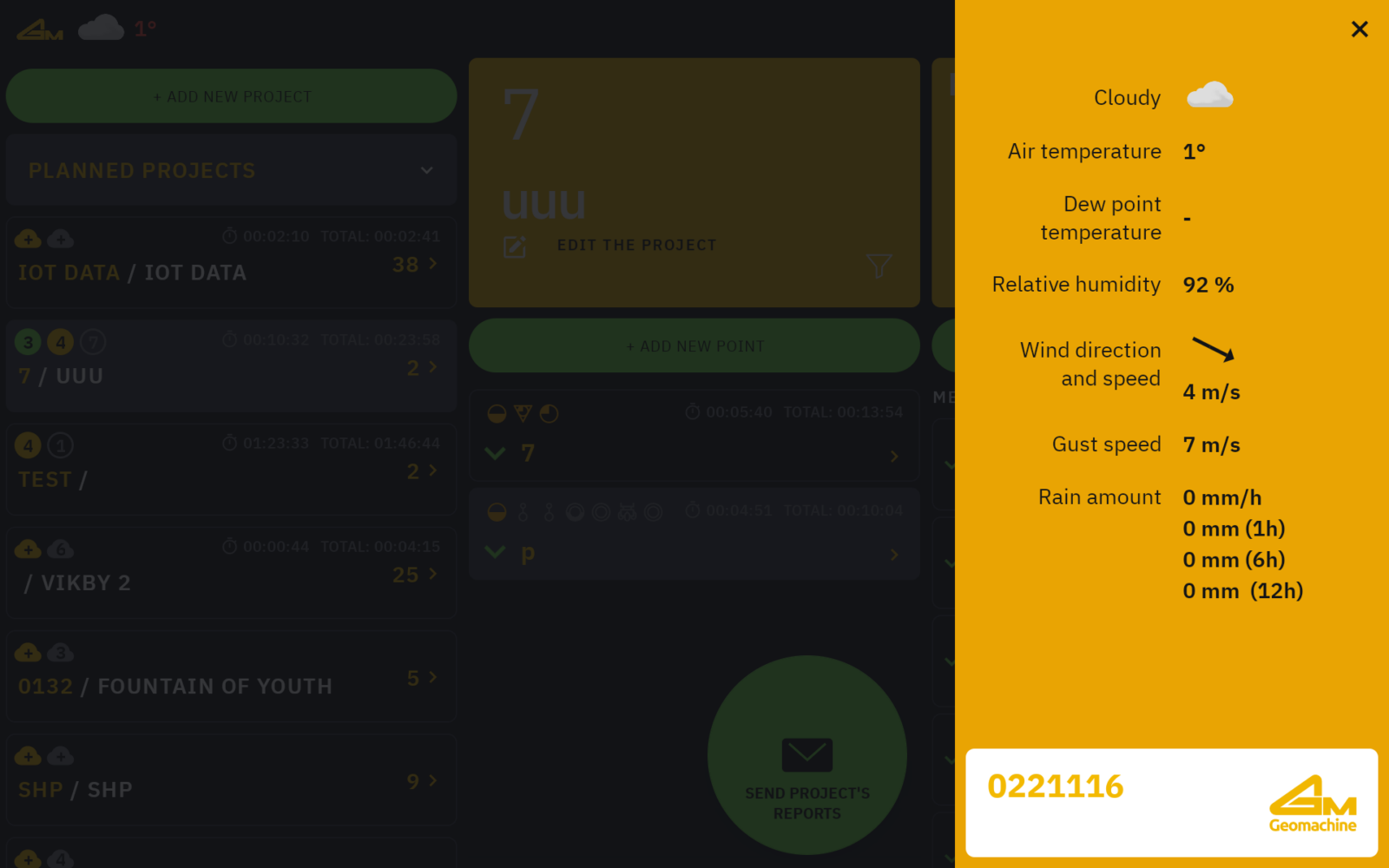

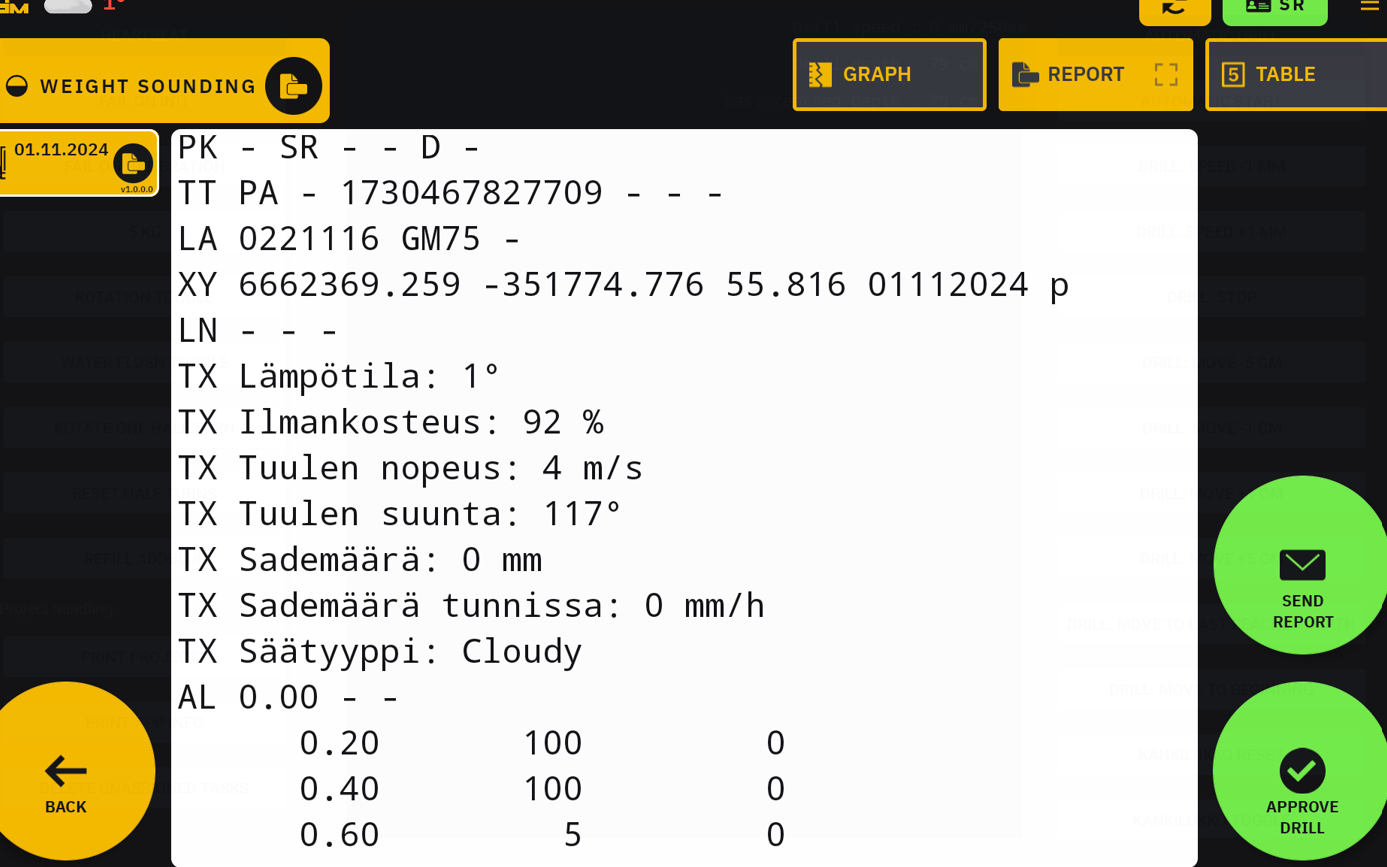

Weather conditions can impact the results of geotechnical investigations, which is why they are documented in the project’s work report. Geomachine has enhanced its GMTracker data-logger with a new feature that records weather data during investigations, allowing this information to be easily integrated into reports.

Geomachine’s GMTracker data-logger is now smarter than ever, thanks to its new weather-tracking feature. This functionality significantly streamlines the work of project managers, as weather information can now be directly copied into the report from geotechnical investigation data. This means that there’s no need to retrieve it separately from a weather service during the report preparation phase anymore.

Using this feature in the GMTracker is straightforward. With the device’s location tracking enabled, the data-logger automatically fetches weather data from a weather service and includes it in the investigation report. Recorded data includes temperature, dew point, precipitation, and wind speed during the investigation.

Geomachine’s GMTracker is currently the only geotechnical data-logger on the market equipped with a weather tracking feature.

Interested? Get in touch!

Vegagerðin

Vegagerðin is an Icelandic state-owned company responsible for managing the country’s roads and infrastructure. The company has recently adopted Geomachine’s GMTrackerCloud service, which enables it to conduct geotechnical investigations in the most intelligent way possible.

Thanks to the GMTrackerCloud service, geotechnical projects can now be carried out more efficiently. The service enables the data-logging, storage, processing, and real-time availability of data for all members of the value chain. “GMTrackerCloud makes the data supply chain smarter,” says Pasi Majakangas, Head of Digital Products at Geomachine. “It reduces the amount of manual work, and the data is always effortlessly accessible to everyone who needs it.”

According to Sverrir Sverrisson, Project Manager at Vegagerðin, GMTrackerCloud is now used by all stakeholders involved in geotechnical projects in Iceland. “Geotechnical engineers upload their drilling plans to Geomachine’s cloud and allocate tasks to the drilling rigs. The field investigator performs the investigations as requested and uploads the data to the cloud service. Geotechnical engineers receive the data in real time from the cloud and can utilize it in their work without delay.”

The activation of the GMTrackerCloud service also eases the workload of field investigators in other ways. “We have implemented a Bluetooth-enabled CPTu solution. This allows the transfer of investigation data wirelessly from the CPTu probe to the GMTracker data-logger. Additionally, we use DGPS positioning, which ensures that the precise location of the investigation point is measured and also saved to the cloud in real time.”

Since Vegagerðin is the sole organization conducting geotechnical investigations in Iceland, the adoption of the GMTrackerCloud service means that the entire country’s investigations are now carried out in a more efficient, high-quality, and intelligent manner.

Interested? Contact us!

Documentation

When considering the development of work machinery, good product documentation is often not the most glamorous or trendy aspect to focus on. However, easy access to information can significantly improve the user experience, operational efficiency, and safety of the machine. Documentation also serves as the backbone of communication between the machine’s user and manufacturer, thereby enhancing not only the operation of the machine but also speeding up the resolution of any issues.

At Geomachine, over the course of a year-long project, we have elevated our user, maintenance, and spare parts documentation to a new level. We began with the development projects of new products, including the GM2000 geothermal drilling rig, the GM22S stabilization rig, and the GMair35 compressor. At the same time, we have also focused on the documentation for ground investigation rigs, and the updated documentation package is now included with all machines delivered from the beginning of this year.

We have thoroughly reviewed the user manuals with an emphasis on safe and efficient operation. The manuals are organized into clear sections at a main level, such as safety, operation, and transportation. The manuals include step-by-step instructions for operating the machine, as well as general and case-specific safety precautions. We have also invested in illustrative visual materials to make the information as easy to understand as possible.

The maintenance instructions are based on years of experience, proven maintenance practices, and the requirements specified by the suppliers of the machine’s various components. Special attention has been paid to daily and frequently recurring maintenance tasks. For example, lubrication points are clearly illustrated with images.

Spare parts manuals are created individually for each machine unit according to a new process, ensuring that the specific differences between machines are taken into account and that the correct parts can be quickly and easily found for each machine. The manuals aim to include the machine’s structure as comprehensively as possible, so that the appropriate part or assembly can be located effortlessly.

The updated documentation is delivered with the machines and is also available in Geomachine’s cloud service, where it is always easily accessible to the customer.

Interested? Contact Geomachine!

GMSampler

Geomachine is constantly developing its product range so that soil investigation can be done more efficiently and profitably. The most recent addition to offering is a sampler that enhances clay soil research.

“As the world’s leading provider of geotechnical, geological and geothermal drilling concepts, it is important for us to constantly develop our product range,” says Alexander Packalen, the COO of Geomachine. “Most recently, we have improved our product offering with a sampler for clay soil investigations. It makes the driller’s work more efficient and improves the quality of the sample.”

In cooperation with a Norwegian partner

Geomachine works closely with the Norwegian soil investigation company NGI. The new sampler was developed by NGI, and in the future its manufacturing will be transferred exclusively to Geomachine.

Kristoffer Kåsin, senior engineer of NGI’s field research, sheds light on the background of the sampler’s product development. “The first hydraulically activated sampler was designed decades ago, in 1952. We created this latest innovation to meet the needs of today’s soil investigation. The two-bar system has previously been used in the samplers. This new sampler can be attached directly to the drill rod, which takes away the need for changing the rod and thus increases the working speed.”

The driving force of the sampler is water pressure. “We came up with the idea of using water pressure, because every soil investigation machine has a water pump. By guiding the water through the hollow drill rod to the sampler, a driving force can be generated to push the sampler into the ground. The empty test tube, on the other hand, is sucked back into the rod with compressed air.”

The new sampler makes work a lot simpler. In addition to saving time, the product also improves the quality of the soil sample. “In the new sampler, the piston rod doesn’t move, which ensures that the sample can be taken from exactly the right depth.”

First for use in the Nordic countries

The sampler will be launched on the soil investigation market during the summer of 2024. Geomachine’s customers in Norway, Sweden and Finland will be the first to get to use it. Currently, there are 54 mm and 72 mm diameter versions of the sampler.

According to Alexander Packalen, the new sampler has been proven to improve the driller’s work and is therefore an innovation that Geomachine is proud of. “Users have praised this new solution as great, well-functioning and easy to use. So we dare to promise that this purchase is worth making for every soil investigation professional who wants their work to become easier and more efficient.”

Interested? Contact us!

Ercüment Akcengiz, BODO Int. GmbH & Co. KG

Growth is strongly embedded in Geomachine’s business strategy and new markets are constantly being conquered. Professional, high-quality resellers play a key role in internationalisation, and Geomachine is constantly looking to expand its network.

The latest additions to our dealer network are Turkish Ercüment Akcengiz and German BODO Int. GmbH & Co. KG.

Geomachine welcomes new dealers!

Find out more:

www.geotra.com.tr

www.bodonet.com