Kategoriat

GeoUnion Oy

GeoUnion is a Finnish company specialising in ground investigation, surveying, and design services. It has relied on Geomachine’s drilling rigs for its ground investigations from the very start of its operations. There are many good reasons behind this long-standing partnership.

Founded in 1993, GeoUnion currently employs around 30 top professionals in the fields of surveying and geotechnics. CEO Markku Savolainen explains that one of the company’s core principles has always been to ensure that its employees have the best possible conditions for success. “Our company’s success is built on our people. From the outset, we decided that our growth wouldn’t be hindered by inadequate tools – and we chose Geomachine as our drilling rig supplier.”

GeoUnion currently operates seven Geomachine rigs, the latest of which was acquired in 2024. “Over the years, we’ve tried other brands, but we’ve found that Geomachine best suits our needs. We work in some of the world’s most challenging environments, and Finland’s dense moraine soils place high demands on drilling rigs. Geomachine’s machines are designed in Finland and perform reliably in our harsh and demanding conditions. That’s why they’re the best choice for us.”

Powerful performance and other outstanding features

GeoUnion’s fleet includes Geomachine drilling rig models GM25, GM75, and GM100. “The GM75 and GM100 are particularly well represented in our fleet. They are excellent multi-purpose machines, with power optimised for their size. They also perform exceptionally well in difficult and demanding terrain.”

However, according to Markku Savolainen, there is something even more important than power and terrain capability. “For us, safety is the number one priority. Geomachine’s machines meet safety requirements extremely well, for example through remote-control capability and excellent work lighting.”

Ground investigations are carried out to understand the conditions below the surface. “I really appreciate how Geomachine has invested in technology development in recent years. The GMTracker data-logger, for example, is an innovation that has clearly streamlined practical work and improved the quality of collected data. Best of all, Geomachine hasn’t just focused on technology but also on ensuring the tool is practical in real-world use. The data-logger doesn’t flinch at cold or outdoor working conditions.”

GeoUnion uses three different Geomachine rig models, and drillers switch between them depending on the investigation requirements. “Geomachine rigs have very similar functionality across models. This makes it much easier for drillers to adapt when switching tools.”

Electrification is part of the future of ground investigation

GeoUnion often takes part in public ground investigation tenders. According to Savolainen, the requirements set for contractors are clearly changing. “We’re seeing clear signs that in future, ground investigations will need to be carried out in a more emission-free and environmentally friendly manner. The minimum requirements for tenderers are becoming stricter and more diverse. We’re definitely heading towards a more electrified ground investigation industry.”

Environmental values are important to GeoUnion and its parent group, Solwers Plc – and these values translate into concrete action. “We calculate our carbon dioxide emissions annually and compare them to previous years. Until now, we’ve reduced emissions mainly through choices in our vehicle fleet, but going forward, we’ll have more opportunities to reduce emissions through our machinery as well. Last year we acquired a GM75 Hybrid, which now enables us to carry out electric ground investigations. We’re also closely monitoring how fully electric rigs are received on the market and how they perform on actual worksites. It’s clear that we must be able to meet the increasing environmental expectations of clients – and we want to ensure we’re fully prepared for that.”

On time, professionally, and competitively

GeoUnion aims to offer its clients the highest possible quality of service, based on three core promises. “We guarantee expert, customer-oriented service. Our clients can also trust that, conditions permitting, we always complete our work on schedule. In addition, we strive to be a competitive option and respond to requests for quotation with comparable pricing.”

GeoUnion continuously takes practical steps to deliver this excellent service experience. “We understand that success stems from customer satisfaction – and customer satisfaction is built on the success of our staff in delivering service. That’s why we invest heavily in ensuring our personnel always have the best tools for high-quality work. We keep our fleet up to date and provide regular training for our team.”

According to Markku Savolainen, Geomachine’s products are a great fit for any Nordic company operating in the geotechnical sector. “If you want an experienced and innovative manufacturer to support your business, with machines that operate efficiently and reliably in tough conditions, Geomachine is the right choice.”

Interested? Contact Geomachine!

Aluetaito Oy

At Aluetaito Oy, the most important aspect of ground investigations is capturing data with the highest possible quality and delivering it swiftly along the project value chain. This commitment has led to a partnership with Geomachine that has lasted over a decade.

Aluetaito provides clients with infrastructure design and investigation services, as well as field surveys and measurements. The service portfolio also includes, among other things, architectural design, BIM modelling, target cost estimates, and zoning for urban and shore areas. The company serves clients primarily within a 200–300 km radius of its headquarters in Lapua and its branch in Rauma.

“When it comes to ground investigations, our mission as a company is clear,” says CEO Juha Porre. “We provide our clients with investigations that are definitely done correctly and in accordance with the investigation programme. We ensure the highest quality of results and complete them on schedule.”

Efficient work made possible by robust tools

At Aluetaito, investigations are carried out with the best available equipment. “We know that if standards are set high, drill operators must be given the best possible conditions to meet them. That means investigation tools and working conditions must support success.”

Currently, Aluetaito uses Geomachine’s GM25, GM50, GM75, and GM8 drill-rig models. “For lighter drilling tasks, we use GM25 and GM50. The GM75 is a great all-rounder, capable of a wide variety of investigations from a single platform. Its compact size also makes it easy to transport between sites. We chose the GM8 as another multi-purpose rig due to its excellent terrain mobility—it has wheels instead of tracks, making it ideal for challenging terrain.”

According to Juha Porre, one key strength of Geomachine’s rigs is their consistent operational logic. “When drill operators use multiple models, it’s beneficial for the machines to function in a similar way. Once they learn one model’s drive, control, and usability, they don’t need to relearn each time they switch to another model. Naturally, this improves both efficiency and quality or work.”

Data at the heart of everything

The final product of a ground investigation is the investigation report—the information about what’s beneath the surface. If this data cannot be captured in high quality, the whole investigation is undermined. “We want to be known as a company whose investigation reports are trustworthy. The reports must always be of the highest possible quality and executed exactly according to the investigation programmes. We’re also known for delivering reports on schedule. Naturally, not all surprises can be foreseen—but when, for example, weather conditions don’t delay work, our reports are produced on time.”

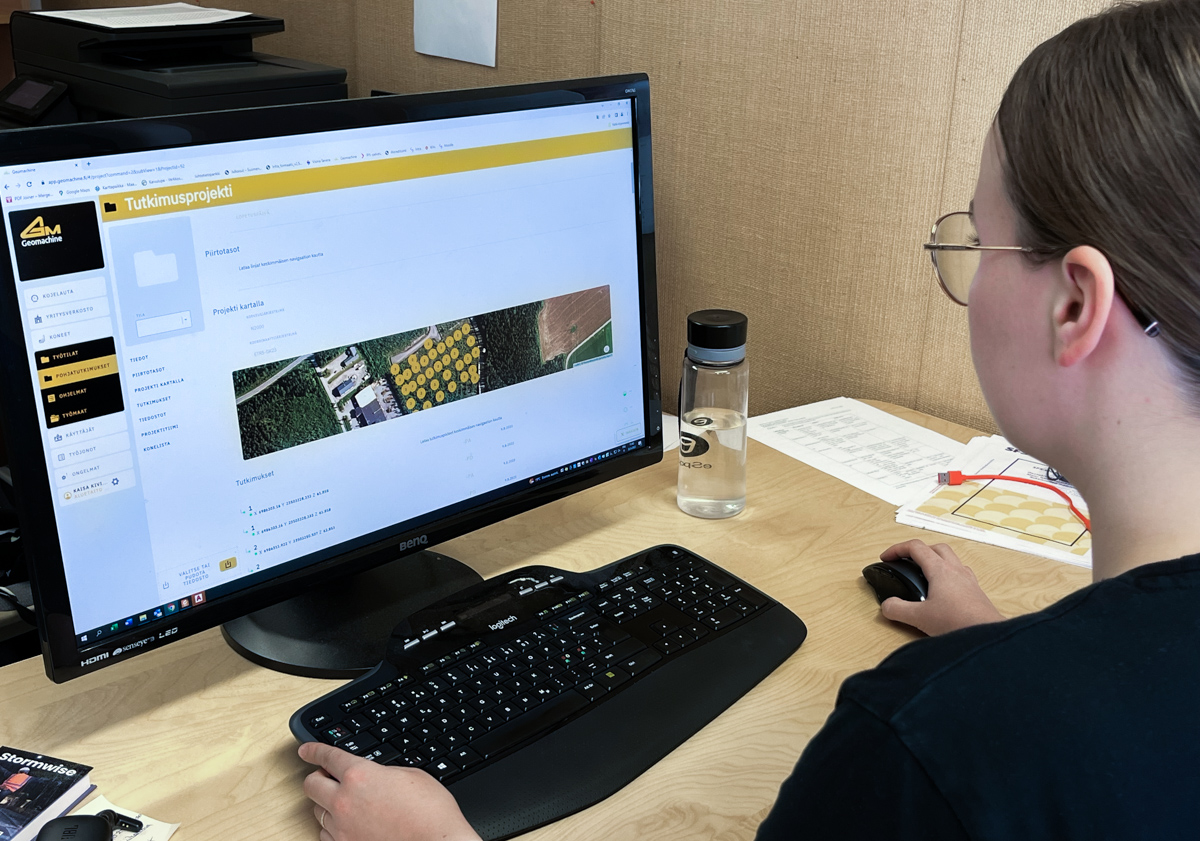

The quality of an investigation report depends heavily on how data is captured. “Geomachine’s technological development of drill-rigs in recent years has been impressive, and today they are incredibly intelligent tools. A concrete example is the GMTracker data-logger designed for collecting ground investigation data.”

Aluetaito was involved in the development of GMTracker and knows its features well. The data-logger—used for about four years—has radically changed their practice. “Project management is now much smoother, as project leaders can distribute investigation programmes to multiple rigs simultaneously. On site, drill operators can view task-specific investigations via the logger and mark them as completed. Not only is data automatically stored in GMTracker, but operators can also add their own observations in it. Manual data entry has become unnecessary now that the level of automation is so high.”

The data-logger has become a popular tool among drill operators. “Since learning how to use the logger, I don’t believe anyone would ever give it up. It’s been an enormous help to operators in their daily work.”

Transparent data flow and increasingly higher utilisation

Thanks to GMTracker’s Cloud version, investigation data is transmitted instantly from the site to everyone who needs it. “Not only can our project management team monitor progress in real time, but our clients also have immediate access to the information. They’ve praised us, noting that they can follow the investigation status without delay and download data as soon as it’s available.”

The Cloud functionality also allows Aluetaito to use the GMCare maintenance service. “We want to maximise the utilisation of our machines, and GMCare is an effective tool for this. At the moment, we mainly use it to document commissioning inspections carried out on site, but in the future it could also help us enhance interaction between the machine operator and maintenance. GMCare uses machine learning, which will enable machines in the future to inform us when maintenance is required.”

For those who want to focus on what matters

Today, a wide range of tools are available to enhance efficiency in ground investigation, and Juha Porre believes companies should definitely take advantage of them. “There are various companies in our sector, each with different operating principles. Our principle is that since the core of ground investigation lies in carrying out investigations correctly and to high quality, that is how we choose to operate. Our strategy for achieving this is to provide our drill operators with the most modern and highest-quality tools available. This is also an investment in the future, as excellent work is the best marketing for an investigation company and a driver of business growth.”

Geomachine’s tools help users focus on what’s essential in investigation work, and are therefore ideal for those whose quality standards and goals are high. “Behind a company’s success is usually the understanding that focusing on the right things is important. Focus improves both work quality and results, which in turn benefits customer satisfaction and drives business.”

Interested? Contact Geomachine!

Taratest Oy

Taratest Oy, a Finnish expert in geotechnical and environmental research, has relied on Geomachine’s drilling rigs for nearly two decades. This article explores Taratest’s experience collaborating with Geomachine.

With over 40 years of history, Taratest employs more than 100 geotechnical professionals and operates offices in Pirkkala, Turku, and Vantaa. “Our mission is to deliver genuinely beneficial, technologically modern, innovative, and cost-effective solutions for construction,” says CEO Tero Mäkinen. “We focus on service quality to foster long-term client relationships, and environmental values are also important to us.”

Taratest’s turnover is approximately €21 million, offering a diverse range of ground and bedrock investigations, geotechnical design, and foundation construction consulting. Additionally, the company conducts environmental studies and assessments serving construction and industry.

A partnership spanning nearly two decades

Taratest ordered its first drilling rig from Geomachine in 2008. “We wanted to replace our outdated machines with equipment from a higher-quality manufacturer. We chose Geomachine because their machines’ advanced features convinced us. In our field, the community is relatively small, and Geomachine had a strong reputation among industry professionals.”

Today, Taratest operates around twenty Geomachine drilling rigs. “We use all Geomachine rig models except the GM8,” Mäkinen notes. “We initially acquired the GM65 rig for its versatility. As our projects became more demanding, we needed larger machines. Now, we have Finland’s most extensive fleet, focusing on larger machines like the GM100, which serves as an excellent heavy-duty multipurpose rig. We were also the first in Finland to acquire the GM100 Hybrid version.”

In the future, Taratest may expand its fleet with the fully electric GMe100 drilling rig. “Most of our projects are public sector works, where environmental friendliness is increasingly emphasized. We aim to be at the forefront of ground investigation, and as electrification is the future in our field, we’re exploring the possibility of adopting this method more extensively.”

Features at the core

Mäkinen highlights that even at the beginning of their collaboration, Geomachine was ahead of competitors in developing features crucial for work efficiency. “Safety has always been our top priority. Even twenty years ago, Geomachine’s machines had advanced protections against rotating parts and crush hazards, surpassing other suppliers.”

Beyond safety features, Geomachine’s rigs offer other strengths. “Their off-road capability is exceptional, which is vital for us as we often work in challenging environments. The machines are also equipped for various research methods, which we highly value. Overall, their usability and reliability are excellent. It’s also beneficial that different models now have similar operational functions, reducing the time operators need to learn new machines.”

In ground investigation, data is the product, and Mäkinen praises Geomachine’s digital capabilities. “The GMTracker data-logger is an incredibly useful tool. Previously, our data-loggers only provided numerical data. In contrast, Geomachine’s data-logger offers a clear graphical interface showing drilling progress, which is highly beneficial. GMTracker automatically records ground properties and machine performance data, reducing manual work for the operator. Operators can also easily add their observations during the investigation. This not only improves data quality but also simplifies quality control of work processes.”

For those seeking the best tools

Mäkinen believes that successful collaboration results from multiple factors. “As a Finnish company, it’s important for us to work with high-quality domestic tools. Geomachine’s expertise in ground investigation methods used in the Nordic countries is exceptional.”

People matter as much as products. “We appreciate that, in addition to reliable machines, we can count on maintenance and support services when needed. It’s also pleasant to work with familiar people, whether considering new equipment purchases or matters related to our current fleet.”

The field of ground investigation is rapidly evolving. “Investigations are becoming more demanding and diverse, increasing expectations for machine performance and intelligence. The importance of data production and quality will continue to grow. Therefore, when acquiring equipment, it’s essential to ensure the supplier can offer digital services that enhance work efficiency alongside traditional drilling rigs.”

Mäkinen concludes that Geomachine is the right choice when aiming to conduct ground investigation with the best available tools. “I believe Geomachine’s drilling rigs and digital products are suitable for all geotechnical companies operating in the Nordic countries. Such that prioritize working with high-quality and reliable rigs—even in extremely challenging conditions.”

Interested? Contact Geomachine!

Vegagerðin

Vegagerðin is an Icelandic state-owned company responsible for managing the country’s roads and infrastructure. The company has recently adopted Geomachine’s GMTrackerCloud service, which enables it to conduct geotechnical investigations in the most intelligent way possible.

Thanks to the GMTrackerCloud service, geotechnical projects can now be carried out more efficiently. The service enables the data-logging, storage, processing, and real-time availability of data for all members of the value chain. “GMTrackerCloud makes the data supply chain smarter,” says Pasi Majakangas, Head of Digital Products at Geomachine. “It reduces the amount of manual work, and the data is always effortlessly accessible to everyone who needs it.”

According to Sverrir Sverrisson, Project Manager at Vegagerðin, GMTrackerCloud is now used by all stakeholders involved in geotechnical projects in Iceland. “Geotechnical engineers upload their drilling plans to Geomachine’s cloud and allocate tasks to the drilling rigs. The field investigator performs the investigations as requested and uploads the data to the cloud service. Geotechnical engineers receive the data in real time from the cloud and can utilize it in their work without delay.”

The activation of the GMTrackerCloud service also eases the workload of field investigators in other ways. “We have implemented a Bluetooth-enabled CPTu solution. This allows the transfer of investigation data wirelessly from the CPTu probe to the GMTracker data-logger. Additionally, we use DGPS positioning, which ensures that the precise location of the investigation point is measured and also saved to the cloud in real time.”

Since Vegagerðin is the sole organization conducting geotechnical investigations in Iceland, the adoption of the GMTrackerCloud service means that the entire country’s investigations are now carried out in a more efficient, high-quality, and intelligent manner.

Interested? Contact us!

Aluetaito

Aluetaito Oy and Geomachine have been collaborating for a decade. Over the years, the customer relationship has evolved into a genuine partnership, playing a significant role in the development of Geomachine’s data-logging software, GMTracker.

“Founded in 2010, our company offers various infrastructure planning and investigation services, as well as field surveys and terrain measurements,” begins Juha Porre, CEO of Aluetaito Oy. “Currently, we employ 13 top professionals in our field and primarily offer our services within approximately a 200-kilometre radius of our main office in Lapua.”

In 2021, Aluetaito began investing in the development of its ground investigation operations. “At that time, we explored the offerings of different drilling equipment suppliers and chose to make our equipment acquisition from Geomachine. One reason for our choice was Geomachine’s in-development data-logging software, GMTracker, which appeared to be a completely new tool in the field of ground investigation. Compared to other available data-logging software, Geomachine’s solution focused specifically on drilling management, which was entirely novel. It very much felt like we were now developing something good that was worth being a part of from the very beginning.”

Development hand in hand

Geomachine designs its products with a strong customer-centric approach and therefore invited Aluetaito to participate in the GMTracker development project. “Our role was to start testing Geomachine’s data-logging software and help them develop a product that serves the needs of customers as well as possible.”

Over a trial period, Aluetaito used GMTracker and GMCloud cloud service in their ongoing projects for two years. “We tried to make the most of them and report our observations to Geomachine in our weekly meetings.”

In addition to user experiences, Aluetaito also made its own suggestions for the development of GMTracker. “We passed on a lot of information to Geomachine about how drilling progresses in practice on our sites. We also made proactive suggestions for improving the software, and these suggestions have been taken into account in product development. For example, we hoped the software would have the ability to share a project set-up in the cloud service with multiple drilling rigs simultaneously. This is an important feature because drilling needs to be carried out with multiple rigs simultaneously in larger projects.”

The first version of the GMTracker data-logging software and the associated GMCloud cloud service have now been launched, but development work continues. “We will continue to provide feedback on the software’s functionality, and we hope that it will also assist in GMTracker’s future product development.”

Overall, more profitable business

GMTracker software enables the world’s first real-time data-logging, processing, visualisation, and transmission of ground investigation data on the same device. Data is stored in real-time in the GMCloud cloud service, making it immediately available to everyone who needs it. The data-logger operates reliably even in challenging weather conditions, and its user interface clarity, ease of use, and logic ensure the software’s usability in the right work situations.

GMTracker is now installed in Aluetaito’s GM50 and GM75 drilling rigs and in another manufacturer’s rig as well. The company has noticed improvements in several areas of its operations since implementing the data-logging software.

“Because the processing of drilling results and data logging are now automated, we save a tremendous amount of time in our practical work. When drillers no longer need to manually transfer the day’s investigation results from their notebooks into electronic format after work, the need for overtime has decreased. Such operational efficiency naturally has a positive impact on the profitability of our business.”

GMTracker and GMCloud also play a significant role in project management. “Our project planners now have an easier time because they can share information about sites and tasks with multiple people simultaneously in the field where the work is done, eliminating the need to print maps and documents. All of this contributes to better project management.”

The benefits are also evident in fieldwork. “With the software, fieldworkers can navigate effortlessly to investigation points and see directly what tasks need to be performed at that point. In larger projects, the software conveniently displays all points and their task lists at once, without the need to check separate pieces of paper.”

Most importantly, also Aluetaito’s customers benefit from the use of GMTracker and GMCloud. “Our customers now have access to higher quality and error-free transfer files, even as they are generated daily in the field. This is a significant help when ground investigation data is needed on a tight schedule.”

For those who value expertise and service

When Aluetaito initially chose a supplier for their drilling equipment, they carefully considered various options. “It seemed that Geomachine had things under control and that assistance was available if needed. We formed a reliable image of a company with which it would be good to work in the long run.”

Based on his own experiences, Juha Porre can recommend Geomachine to companies in the ground investigation field that value expertise and customer service. “If the goal is to find a partner whose products are high-quality and up-to-date, with a high level of customer service, Geomachine is the right choice.”

Read more about GMTracker here.

QHeat

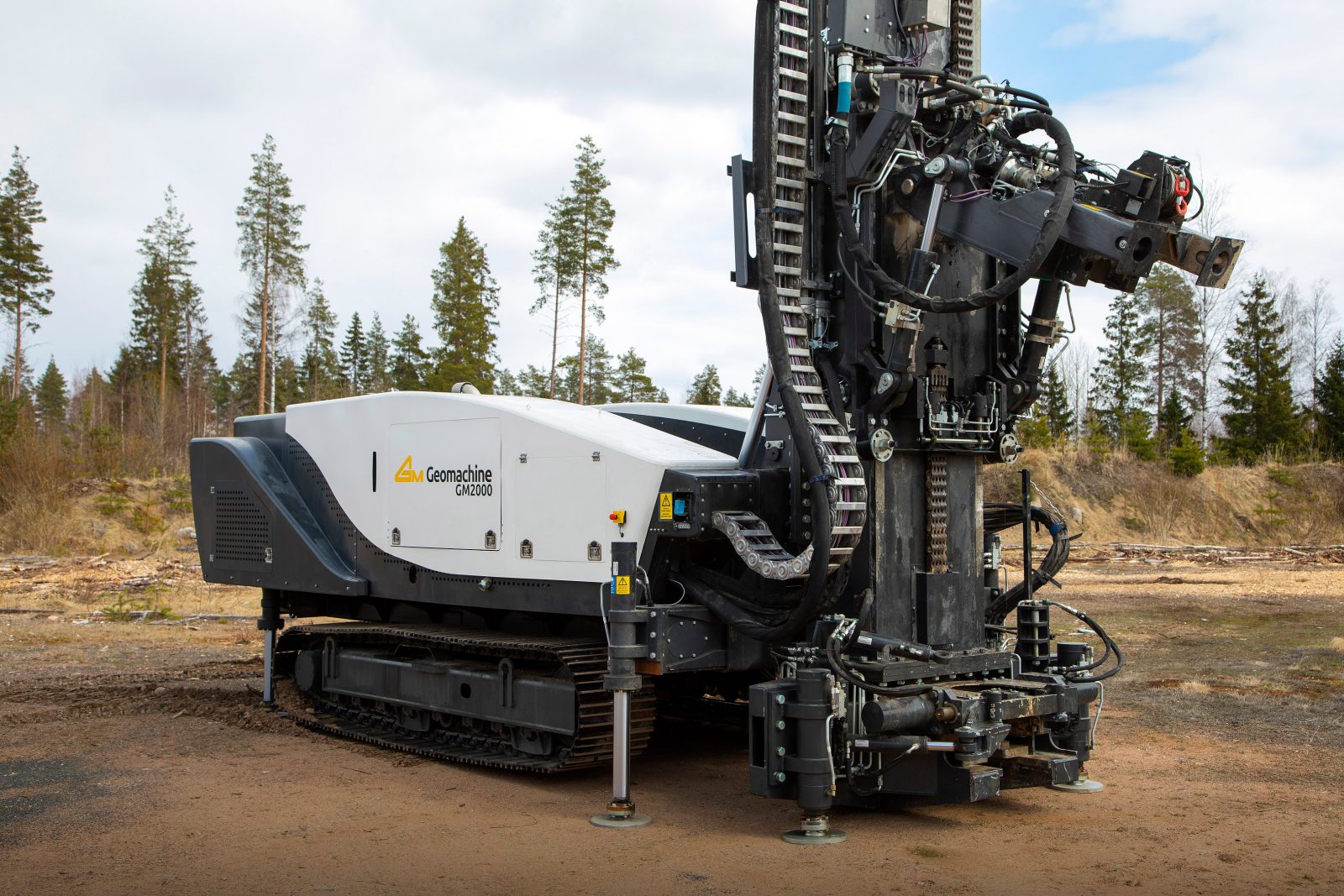

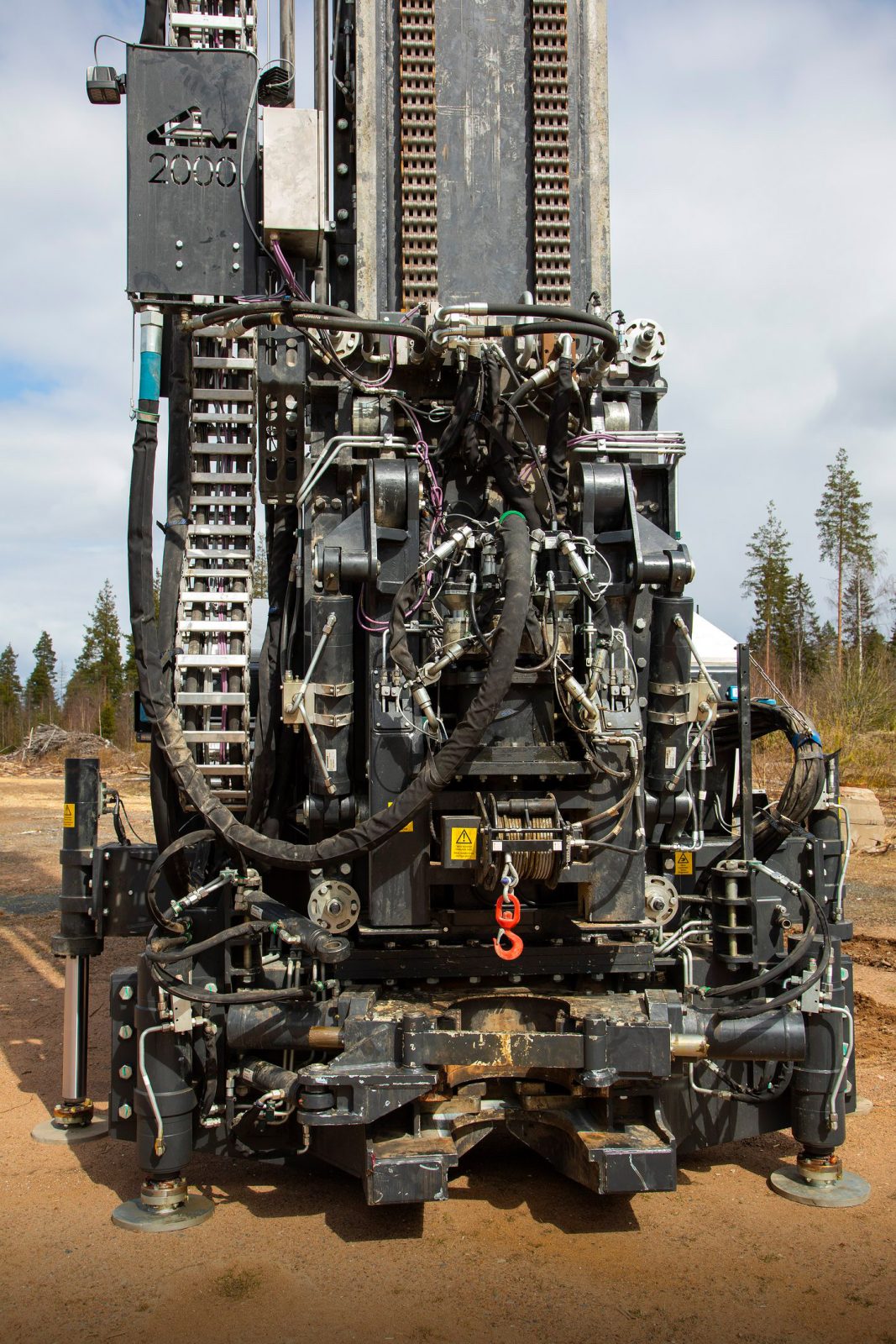

Thanks to the new geothermal solution introduced in March 2023, geothermal heat is now being captured from depths exceeding 2000 metres. The developer behind this solution is the technology company QHeat. Well drilling is carried out using Geomachine’s GM2000 technology.

“Deep drilling has been a practice in the oil and gas sector for a long time,” begins Erika Salmenvaara, CEO of QHeat. “However, in traditional geothermal drilling, the depth has only been around 300 metres. With our newly developed geothermal well solution, we are now able to utilise geothermal energy from up to 2000 metres deep, and possibly even deeper in the future. This represents a significant leap in the utilisation of geoenergy.”

QHeat’s new geothermal solution is patented globally. “We will also take our innovation abroad. Energy consumption is continuously increasing, and there is a growing demand for renewable energy sources. Geothermal energy holds immense market potential in Europe, North America, and Asia.”

GM2000 takes centre stage in drilling

The drilling of wells is performed using Geomachine developed GM2000 well drilling technology. In addition to the well drilling rig, the complete solution includes a compressed air system and an intelligent control and recording system for optimising the drilling process. This solution is the first of its kind in the world. “When we started looking for a practical implementer for our innovation a few years ago, we realised that there was no expertise in deep geothermal well drilling in Finland. Geomachine has decades of experience in ground investigation and down-the-hole hammer drilling, so we engaged in discussions about refining our concept with them. It became clear that they had the expertise needed to develop the drilling rig.”

In designing the GM2000 well drilling rig, special attention has been given to overall cost-effectiveness, automatic data recording, real-time analysis of the drilling process, and work safety. “The adoption of the GM2000 solution has brought various benefits. Drillers’ job satisfaction has improved because they now have a modern tool at their disposal. Work is safer, and drillers are no longer exposed to emissions as the rig can be controlled remotely. Due to the rig’s data-driven control, the driller knows what is happening in the hole at all times. Overall, work has become safer and of higher quality.”

In action at a waste incineration plant

The world’s first GM2000 well drilling rig was put into operation in March 2023 at the request of Lounavoima, a waste incineration plant in Salo, Finland. “Our customer specifically required the use of this solution for their site. In addition to greater drilling depth, safety during work was important to our customer.”

At the Lounavoima waste incineration plant, deep geothermal wells are primarily used for heat storage. “The plant generates a steady stream of energy for the district heating network. However, the heat demand on the network constantly varies. During periods of low consumption, the plant has generated excess heat. This excess heat can now be stored in deep geothermal wells and later released when demand increases. This solution was not previously used at waste incineration plants, so we are implementing it here as the first in the world.”

The Lounavoima project began in 2021 with a different drilling rig, and now it continues with Geomachine’s GM2000 solution. “The plan is to drill two more geothermal wells this year, totaling three wells at the site. Overall, the goal is to create a heat storage consisting of six wells.”

Clear numbers tell the story

Before the introduction of the GM2000 well drilling rig, the record drilling depth for geothermal wells was 1600 metres. The ability to now drill to 2000 metres, and potentially even deeper in the future, takes the utilisation of geothermal energy to a whole new level. “The drilling depth has been increased by a third, which means that now we can capture 60% more energy than before. From a 1500-metre deep well, we obtained 950 megawatt-hours annually, and from a 2000-metre deep well, we can now obtain 1530 megawatt-hours. This is a remarkable improvement!”

The numbers are even more impressive when comparing the energy output of a 2000-metre deep well to a traditional 300-metre deep geothermal well. “Compared to a traditional well, we can now capture over 60 times more energy from a single well.”

In the future, the GM2000 solution will benefit especially large real estate properties where the solution can be used as a regional energy source. The energy from a single well is sufficient to heat even 300 energy class A apartments size of 70 m².

“In the future, we will market our solution especially to large property owners, professional real estate investors, construction companies, district heating producers, and district heating companies. The target must be large enough to optimally benefit from our solution.”

Authentic collaboration

According to Erika Salmenvaara, the collaboration with Geomachine is an excellent example of how combining forces can lead to an excellent outcome. “Our mission is to assist our customers on their carbon neutrality journey, particularly in heating. Our product is clean heating energy. Geomachine, on the other hand, offers the solution for practically implementing our mission. Even though we operate in different industries, we have found true synergy in achieving a common good.”

Both QHeat and Geomachine benefit from this collaboration in growing their respective businesses. “For us, collaboration enables us to sell our innovation as a tangible product to those who need it. Geomachine, on the other hand, adds a new solution to their product portfolio, expanding their offerings from ground investigation to geothermal energy drilling.”

Read more about GM2000 solution here.

Kenneth Reiersen

Norwegian Kenneth Reiersen has had a long career in soil investigation. As a work partner, Kenneth has almost always had Geomachine and recently it became very close to him. Literally.

My career in geotechnical soil investigation started in 2008. After that, my employers have been Statens Vegvesen, Norconsult AS and right now Mesta AS,” Kenneth Reiersen begins. “To date, I have gained 15 years of work experience in the field.”

For most of his career, Kenneth has worked with Geomachine’s geotechnical drilling rigs. So far, the drilling rig models GM85, GM100, GM200 and GM8 have become familiar to him. “I also have experience with other drilling rig brand, but Geomachine has become my absolute favorite over the years. I consider Geomachine’s off-road capability to be the most important feature that makes my work more efficient. Thanks to the solid structure, stability and strength of the rigs, they are reliable in all kinds of conditions, even in very challenging ones. You can easily work with them, for example, in deep snow or on steep slopes.”

According to Kenneth, Geomachine’s drilling rigs and the company’s operating methods also have other winning features. “One of the finest technical innovations that concretely enhances soil investigation procedure is the machine’s double rod lock feature. Thanks to it, I don’t have to use separate keys to open the bar joints, which improves work safety and simplifies and makes almost all investigation activities more efficient. It’s also great that Geomachine does continuous product development and wants to hear my, the machine user’s, opinions about what kind of development would make the machines even more superior in use.”

GM100 for use straight from the factory

In November 2022, Kenneth received a brand new GM100 drilling rig into use directly from Geomachine’s Tuusula factory. Expectations set for the new machine are high. “I already have experience with the GM100 drilling rig, so I know what to expect. But this is the first time I get to use the machine brand new. I am sure that this new machine of mine will be of the same series as my previous Geomachines. That is, stable, reliable and extremely efficient”.

Kenneth is particularly pleased that his new machine is a GM100 drilling rig. “According to my experience, the GM100 is the most perfect model for use when the same rig has to perform many different tasks.”

Sometimes support may also be needed after the machine has been driven from the factory to the work site. “Geomachine’s Norwegian dealer and service partner PTO Teknikk AS is an invaluable help to me in all my questions related to the use of the machine. They are always ready to help and when maintenance or repair needs arise, they provide service very quickly. Best of all, they are not only my maintenance and service partner, but also constantly teach me new things about the machines.”

Markable brand loyalty

Geomachine has recently become very close to Kenneth, literally. “When my employer Mesta was considering the purchase of our next Geomachine, I decided to do something very special. I told my contact person at PTO Teknikk, Robin Jensen, that I would come to get a Geomachine-themed tattoo if the order came true. And so it turned out. Now I have the Geomachine logo and GM100 rig tattooed on my arm!”.

So who does Kenneth think Geomachine is the best tool for? “In my opinion, Geomachine is the best option for a driller who wants to perform his work with the highest possible quality and cost-effectiveness. I can unreservedly give Geomachine five stars, but a small warning is in order here. These machines might make you really enjoy spending time at work, because thanks to them you might fall in love with your job in a whole new way!”

SWECO NORGE AS / SWECO FELT NARVIK

Sweco plans and designs the sustainable communities and cities of the future. As a result, they are able to achieve sustainable construction and functional infrastructure, in addition to enabling the supply of electricity and clean water.

Sweco employs a total of 17,500 people in northern Europe to ensure that the company’s customers receive just the right expertise and know-how for their various projects. Every year, the company is involved in different projects in some 70 countries worldwide.

Sweco’s net sales are around two billion euros, and the company is listed on NASDAQ OMX Stockholm AB.

Sweco established its own ground investigations department on January 2019 under the leadership of two former drilling directors from the Norwegian road administration. The directors have experience of several different types of drilling rigs and have been using the GM8 and ENVI rigs since 2011.

With the help of Sweco Sverige, the field department started operations when it acquired a GM75 rig equipped with ENVI. The lightweight soil investigation rig was an excellent 2012 model but was somewhat outdated and did not have a compressor onboard. In 2020 we decided to purchase a new drilling rig, and acquired a GM100 track-mounted rig with the same sturdy mast the GM8 model has. We chose Geomachine because our drilling managers are familiar with these rigs and the ENVI drilling system

Stig Bjarne Larsen, Director of Drilling Operations

It was important for SWECO FELT NARVIK to acquire a rig that was tried and tested and already familiar to the staff.

The company needed a drilling rig that had been proven in the field and met all requirements. The climate in northern Norway is cold, the terrain is rough and distances to the nearest repair shops are long. Geomachine supplies spare parts quickly and their customer service operates around the clock, every day of the year. Geomachine also has a reliable maintenance representative in Norway – PTO Teknikk based in Oslo.

Read more about the company here.

AFRY / ÅF PÖYRY AB

The story of AFRY began in the Swedish city of Malmö 125 years ago. Today, AFRY employs more than 16,000 devoted experts within the fields of infrastructure, industry and energy, operating across the world to create sustainable solutions for the next generation. AFRY has offices in more than 40 countries and manages projects in more than 100. AFRY currently operates a large number of Geomachine soil investigation rigs in the Nordic countries carrying out operations in geotechnics and rock engineering.

In my opinion, the usability of Geomachine drilling rigs in snow, is considerably better than other brands we have tried. The support received from Geomachine when there is a problem has been excellent, which is why our trust in them is solid. When there is a problem, Geomachine staff are quickly on site to rectify any issues, which is phenomenal service and also a prerequisite for us to operate in the field.

Jörgen Noppa, Team Leader, Field Geotechnics

AFRY field geotechnicians, Evelina Almqvist and Rickard Sundström, are also happy with Geomachine products. Evelina currently operates a GM85 and Rickard a GM8. Both drilling rigs are equipped with the new CAN bus system.

Rickard and Evelina feel the rigs’ top features are their easy operability and the option for all drilling tasks to be performed by remote control. Geomachine drilling rigs operate much better in deep snow than other rig brands they have tried. If there are ever any problems, Evelina and Rickard state that Geomachine support has always been just a phone call away.

Read more about the company here.

Konepörssi, 25 January 2021

Geomachine Oy has delivered the world’s first electrically-propelled drilling rig for soil investigation to Multiconsult Ab in Norway. In addition to a diesel engine, the rig is equipped with an electric motor that can be used to move it as well as perform drilling operations.

Read the entire article in the Konepörssi magazine here.

Norwegian TU Building has also published a story about the Geomachine Hybrid rig. The article can be found here.